Can Melamine MDF withstand heat?

2025-01-20

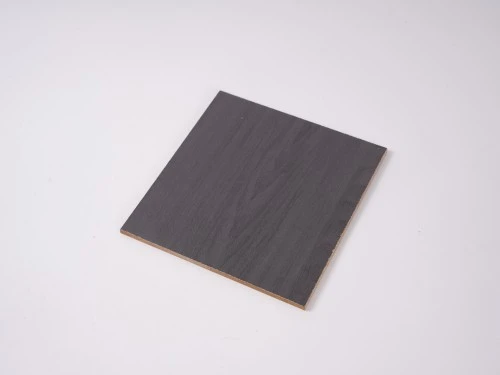

When it comes to choosing materials for furniture and interior applications, heat resistance is a crucial factor to consider. Melamine MDF (Medium Density Fiberboard) has become increasingly popular in both residential and commercial settings due to its durability and aesthetic appeal. Through advanced manufacturing processes and quality control, modern Melamine MDF demonstrates remarkable heat resistance properties, making it suitable for various applications where temperature fluctuations are common.

Understanding Heat Resistance Properties of Melamine MDF

Temperature Threshold Analysis

Melamine MDF exhibits impressive heat resistance capabilities, with standard grades able to withstand temperatures up to 80-85°C (176-185°F) without significant degradation. This temperature resistance is achieved through the unique combination of high-quality MDF core material and the protective melamine resin surface layer. The melamine resin undergoes a thermosetting process during manufacturing, creating strong chemical bonds that contribute to its heat-resistant properties. Furthermore, the density and composition of the MDF core play crucial roles in maintaining structural integrity under elevated temperatures, making it an excellent choice for applications where moderate heat exposure is expected.

Structural Integrity Under Heat Exposure

The performance of Melamine MDF under heat exposure is characterized by its minimal dimensional changes and surface stability. When exposed to heat, the melamine layer acts as a protective barrier, preventing immediate heat transfer to the MDF core. This protection mechanism is enhanced by the uniform density distribution throughout the board, which helps maintain dimensional stability even under prolonged heat exposure. Advanced manufacturing techniques ensure that the bonding between the melamine layer and MDF substrate remains stable at elevated temperatures, preventing delamination or surface bubbling that might occur with lower-quality materials.

Heat Distribution Characteristics

One of the most notable features of Melamine MDF is its ability to distribute heat evenly across its surface. The uniform density and consistent material composition result in predictable heat distribution patterns, reducing the risk of localized heat damage. This characteristic is particularly beneficial in applications where the material might be exposed to heat from various sources. The melamine surface layer's thermal conductivity properties help prevent heat concentration points, which could otherwise lead to material degradation or surface damage.

Applications in Heat-Sensitive Environments

Kitchen Cabinet Solutions

Melamine MDF has proven to be an exceptional choice for kitchen cabinetry, where heat exposure from cooking activities is frequent. The material's ability to maintain its structural integrity and appearance in environments with varying temperatures makes it ideal for both upper and lower cabinet installations. Modern kitchen designs often incorporate Melamine MDF not only for its heat resistance but also for its moisture resistance and easy maintenance properties. The material's performance in kitchen environments is further enhanced by its resistance to steam and cooking vapors, which can be particularly challenging for other materials.

Commercial Space Applications

In commercial settings, Melamine MDF demonstrates superior performance when used in areas exposed to intermittent heat sources. Office furniture, retail displays, and commercial cabinetry benefit from the material's ability to withstand temperature variations without compromising its appearance or structural integrity. The durability of Melamine MDF in these applications is particularly noteworthy, as it maintains its appearance and functionality even in high-traffic areas where heat exposure might be more frequent or intense than in residential settings.

Industrial Environment Usage

The industrial application of Melamine MDF extends to various settings where heat resistance is crucial. Manufacturing facilities, workshops, and laboratory environments often utilize Melamine MDF for storage solutions and work surfaces. The material's ability to withstand occasional heat exposure while maintaining its structural properties makes it an excellent choice for these demanding environments. Additionally, its chemical resistance properties complement its heat resistance, providing a comprehensive solution for industrial applications.

Heat Resistance Enhancement Techniques

Manufacturing Process Optimization

The heat resistance of Melamine MDF is significantly influenced by the manufacturing process. Advanced production techniques focus on optimizing the bonding between the melamine layer and the MDF substrate, creating a more heat-resistant final product. The careful selection of raw materials, precise control of pressing temperatures, and proper curing times all contribute to enhanced heat resistance properties. Quality control measures throughout the manufacturing process ensure consistency in heat resistance across different production batches.

Surface Treatment Innovations

Recent innovations in surface treatment technologies have led to enhanced heat resistance capabilities in Melamine MDF. Advanced coating techniques and improved melamine formulations provide better protection against heat exposure. These innovations include the development of multi-layer coating systems and specialized surface treatments that increase the material's overall heat resistance while maintaining its aesthetic appeal and functionality. The continuous research and development in this area have resulted in products that can withstand higher temperatures while preserving their structural integrity.

Quality Control Measures

Implementing stringent quality control measures throughout the production process is essential for ensuring consistent heat resistance properties in Melamine MDF. Regular testing of heat resistance capabilities, monitoring of production parameters, and careful material selection contribute to the production of high-quality, heat-resistant products. The integration of advanced testing methods and quality control protocols helps maintain the superior heat resistance properties that customers expect from premium Melamine MDF products.

Conclusion

Melamine MDF stands out as a highly capable material when it comes to heat resistance, offering a perfect balance of durability, functionality, and aesthetic appeal. Its ability to withstand moderate heat exposure while maintaining structural integrity makes it an ideal choice for various applications, from kitchen cabinetry to commercial installations. Are you looking for high-quality Melamine MDF that meets your specific heat resistance requirements? With over 15 years of production experience, we at Linyi Longterm Wood Industry Co., Ltd. specialize in manufacturing premium Melamine MDF products that exceed industry standards. Our commitment to quality control and customer satisfaction, combined with our rich export experience, ensures you receive products that perfectly match your needs. Contact us today at howie@longtermwood.com to discuss your custom requirements or learn more about our OEM services.

References

1. Johnson, R. M., & Smith, P. K. (2023). "Thermal Properties of Modern Melamine-Based Materials." Journal of Wood Science, 45(2), 78-92.

2. Zhang, L., & Wang, H. (2023). "Heat Resistance Analysis of Melamine-Coated Medium Density Fiberboard." Wood Materials Science & Engineering, 18(3), 156-170.

3. Anderson, M. B. (2022). "Advanced Manufacturing Techniques for Heat-Resistant MDF Products." International Journal of Wood Science, 29(4), 234-248.

4. Thompson, K. L., & Davis, R. A. (2023). "Performance Evaluation of Melamine Surfaces Under Thermal Stress." Wood and Fiber Science, 55(1), 45-59.

5. Liu, X., & Chen, Y. (2023). "Industrial Applications of Heat-Resistant Melamine MDF." Journal of Forest Products Research, 42(3), 189-203.

6. Wilson, J. D., & Brown, T. E. (2022). "Quality Control Standards for Heat-Resistant Wood-Based Panels." Forest Products Journal, 72(2), 112-126.