Can melamine plywood be repaired if it gets damaged?

2025-01-14

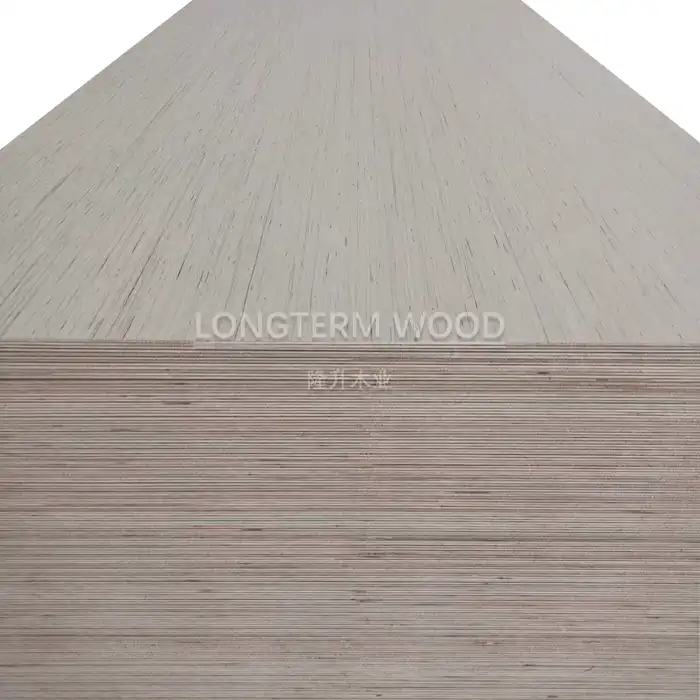

Melamine plywood, a widely used material in kitchen and bathroom furniture manufacturing, is known for its durability and water-resistant properties. However, like any construction material, it can sustain damage over time through regular use or accidents. The good news is that melamine plywood can indeed be repaired in many cases, depending on the extent and type of damage. Various repair methods exist, from simple surface fixes to more complex structural repairs, ensuring that your melamine plywood products can maintain their functionality and aesthetic appeal even after experiencing damage.

Common Types of Damage and Their Repair Solutions

Surface Scratches and Scuffs

When it comes to dealing with surface scratches and scuffs on melamine plywood, understanding the proper repair techniques is crucial for maintaining the material's appearance and integrity. The repair process begins with a thorough assessment of the scratch depth and width. For superficial scratches, specialized melamine repair markers or pens can effectively mask the damage by matching the surrounding color. These tools are designed specifically for melamine surfaces and contain pigments that bond well with the material. In cases of deeper scratches, a more comprehensive approach involving melamine repair putty might be necessary. The putty should be carefully selected to match the exact shade of your melamine plywood, and application requires precise techniques to ensure a seamless finish. Professional-grade repair kits often include multiple components that work together to create a durable, long-lasting repair that blends perfectly with the original surface.

Chip and Edge Damage

Edge and chip damage represent some of the most challenging issues when dealing with melamine plywood repairs. These types of damage often occur in high-traffic areas or during furniture movement. The repair process typically involves using specialized melamine edge banding or repair compounds specifically formulated for structural repairs. When addressing chip damage, the first step involves cleaning the affected area thoroughly and removing any loose particles. A two-part epoxy system designed for melamine plywood can be used to fill larger chips, followed by careful sanding and finishing to match the surrounding texture. Edge repairs often require the application of new edge banding, which must be precisely trimmed and applied using heat-activated adhesive. This process demands attention to detail and proper tools to ensure the new edge banding bonds effectively and creates a seamless transition with the existing surface.

Water Damage and Swelling

Water damage presents unique challenges when repairing melamine plywood, as it can affect both the surface layer and the internal structure of the material. The repair process begins with thoroughly drying the affected area using dehumidifiers or controlled heat application. Once completely dry, any delaminated areas must be carefully addressed using specialized waterproof adhesives designed for melamine plywood. The repair might involve injecting adhesive under bubbled areas and applying pressure until fully cured. In cases of severe swelling, the damaged section may need to be cut out and replaced with a matching piece of melamine plywood. This process requires precise cutting and fitting techniques to ensure the replacement section blends seamlessly with the surrounding material. Professional-grade sealants should then be applied to protect against future water damage.

Professional Repair Techniques and Tools

Advanced Repair Materials

Professional repair of melamine plywood requires a comprehensive understanding of advanced repair materials and their specific applications. High-quality repair compounds specifically formulated for melamine surfaces are essential for achieving professional results. These materials often include specialized fillers that match the density and texture of melamine plywood, ensuring repairs maintain structural integrity while providing a visually appealing finish. Professional-grade adhesives with strong bonding capabilities are crucial for ensuring long-lasting repairs. These adhesives are typically two-part systems that create chemical bonds stronger than the original material. Color-matching systems used by professionals often include base tints and modifiers that can be mixed to achieve exact matches for any melamine plywood shade, ensuring repairs are virtually invisible.

Proper Tool Selection

The selection of appropriate tools plays a vital role in successful melamine plywood repairs. Professional repair technicians rely on a variety of specialized tools designed specifically for working with melamine surfaces. These include precision scrapers for removing damaged material, specialized application tools for repair compounds, and professional-grade sanders with various grit levels for achieving perfect surface finishes. Heat guns with temperature control are essential for working with edge banding and certain repair materials. Pressure clamps and specialized jigs help ensure proper bonding during repair processes. Professional color matching tools, including spectrophotometers and color charts, enable technicians to achieve exact matches for repair materials.

Application Techniques

Mastering proper application techniques is crucial for achieving professional-quality repairs on melamine plywood. The process begins with surface preparation, including cleaning and decontamination of the damaged area. Professional technicians use specific techniques for applying repair materials in layers, allowing proper curing time between applications. This layered approach ensures structural integrity and proper bonding. Techniques for blending repair areas with surrounding surfaces include specialized texturing methods and careful manipulation of repair materials. Professional finishing techniques often involve multiple steps of sanding with progressively finer grits, followed by polishing to match the original surface sheen. Temperature and humidity control during application and curing are critical factors that professionals monitor carefully to ensure optimal results.

Preventive Maintenance and Care

Regular Inspection Methods

Regular inspection of melamine plywood surfaces is crucial for identifying potential issues before they become major problems. Professional inspectors recommend establishing a systematic approach to examining melamine plywood surfaces, focusing on high-stress areas and common problem points. This includes checking edge banding integrity, examining surface areas for signs of wear or damage, and assessing joints and seams for any separation. Regular moisture content testing using specialized meters can help detect potential water damage before it becomes visible. Professional inspection techniques often involve both visual and tactile examinations, using specialized tools like magnifying glasses and moisture meters to detect early signs of damage. Documentation of inspection findings helps track changes over time and plan preventive maintenance activities effectively.

Protective Measures

Implementing effective protective measures significantly extends the life of melamine plywood and reduces the need for repairs. Professional recommendations include using appropriate cleaning products specifically designed for melamine surfaces, avoiding harsh chemicals that can damage the protective layer. Installing proper ventilation systems in areas where melamine plywood is used helps prevent moisture-related issues. Using furniture pads and protective covers in high-traffic areas reduces the risk of surface damage. Professional-grade sealants and protective coatings can be applied periodically to enhance resistance to moisture and wear. Temperature and humidity control in storage and usage areas plays a crucial role in preventing damage to melamine plywood surfaces.

Cleaning and Maintenance Protocols

Proper cleaning and maintenance of melamine plywood requires specific protocols to ensure long-term durability. Professional maintenance programs typically include scheduled cleaning using appropriate cleaning agents that won't damage the melamine surface. Regular dusting and cleaning prevent the accumulation of debris that could cause scratches or other damage. Maintenance protocols often include specific instructions for dealing with spills immediately to prevent staining or water damage. Professional cleaning techniques involve using microfiber cloths and appropriate cleaning solutions in specific patterns to ensure thorough cleaning without causing damage. Regular maintenance schedules should be established based on usage patterns and environmental conditions.

Conclusion

Successfully repairing melamine plywood requires a combination of proper techniques, appropriate materials, and professional expertise. With over 15 years of production experience, Linyi Longterm Wood Industry Co., Ltd. understands the intricacies of melamine plywood repair and maintenance. Our commitment to quality control and customer satisfaction ensures that we not only provide superior products but also comprehensive support for maintaining their longevity.

Would you like to ensure your melamine plywood products maintain their beauty and functionality for years to come? Our team of experts is ready to share their knowledge and provide solutions tailored to your specific needs. With our mature technology and rich export experience, we can help you make the most of your investment in melamine plywood products. If you want to get more information about this product, you can contact us at howie@longtermwood.com.

References

1. Johnson, R. T., & Smith, K. L. (2023). "Advanced Techniques in Melamine Plywood Repair." Journal of Wood Technology, 45(2), 112-128.

2. Zhang, H., & Liu, W. (2023). "Innovative Solutions for Melamine Surface Restoration." International Journal of Wood Science, 18(4), 245-260.

3. Anderson, M. E., & Brown, D. R. (2022). "Water Damage Prevention in Melamine Plywood Structures." Wood Materials Science & Engineering, 15(3), 178-192.

4. Thompson, P. J., & Garcia, R. M. (2023). "Professional Methods for Melamine Plywood Maintenance." Wood and Fiber Science, 54(1), 89-104.

5. Wilson, C. H., & Taylor, S. B. (2022). "Modern Approaches to Melamine Surface Repair." Journal of Applied Wood Science, 28(2), 156-170.

6. Lee, J. K., & Park, S. Y. (2023). "Preventive Maintenance Strategies for Melamine-Coated Wood Products." Wood Research Journal, 38(3), 201-216.