Can Melamine Plywood Be Used in High-Humidity Areas Like Bathrooms?

2025-02-26

Homeowners and interior designers often face challenges when selecting materials for high-moisture environments like bathrooms. One common question that arises is whether melamine plywood is suitable for such spaces. This comprehensive guide explores the viability of melamine plywood in bathrooms and other humid areas, examining its properties, benefits, and considerations to help you make an informed decision for your next renovation or construction project.

Understanding Melamine Plywood's Moisture Resistance

When considering materials for humid environments like bathrooms, kitchens, or laundry rooms, moisture resistance becomes a critical factor. Melamine plywood offers a compelling solution for these challenging spaces, though with some important qualifications.

The Structure Behind Moisture Resistance

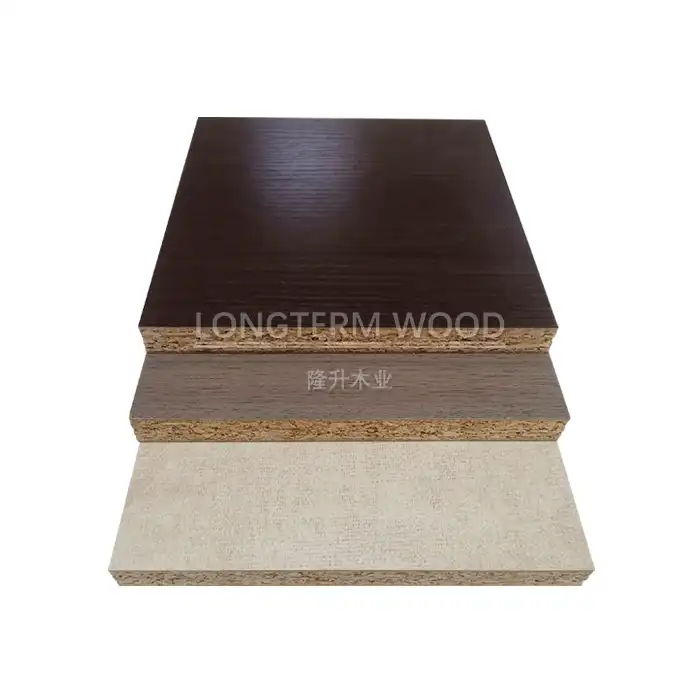

Melamine plywood is engineered with moisture resistance in mind. The core consists of multiple layers of wood veneer bonded together with high-quality adhesives, while the surfaces are sealed with melamine resin—a durable, non-porous material. This construction creates a barrier against moisture penetration that standard plywood lacks. The melamine coating acts as the first line of defense, preventing water droplets from making direct contact with the wooden substrate. Additionally, quality manufacturers like Linyi Longterm Wood Industry Co., Ltd. utilize water-resistant adhesives between plywood layers, creating multiple barriers against moisture infiltration. This multi-layered protection system significantly extends the material's lifespan in humid conditions, making melamine plywood a practical option for bathroom applications when properly sealed and maintained. The material's inherent resistance to moisture absorption helps prevent the warping, swelling, and delamination that often plague traditional wood products in high-humidity areas.

Moisture Resistance Limitations

While melamine plywood offers enhanced moisture resistance compared to standard plywood, it's important to understand its limitations in extremely wet environments. The melamine coating primarily protects the surface, but edges and cut sections remain vulnerable to water penetration unless properly sealed. When melamine plywood is constantly exposed to standing water or experiences frequent direct water contact, the protective barriers may eventually break down. This vulnerability is particularly evident at joints, edges, and any drilled holes, where the unprotected core can absorb moisture. High-quality melamine plywood from reputable manufacturers like Linyi Longterm Wood Industry typically performs better under these conditions, as they use superior water-resistant adhesives and more durable melamine coatings. However, even the highest-quality melamine plywood should not be considered fully waterproof. For installations in bathroom areas with direct and frequent water exposure, additional protective measures such as edge banding, specialized sealants, and careful installation techniques are necessary to maximize the material's moisture resistance and ensure long-term performance.

Performance Comparison with Other Materials

When evaluating melamine plywood against other bathroom-suitable materials, its unique balance of properties becomes apparent. Compared to solid wood, melamine plywood offers significantly better dimensional stability when exposed to humidity fluctuations—a common challenge in bathroom environments where shower steam causes rapid humidity changes. Unlike natural wood that readily absorbs atmospheric moisture, causing expansion and contraction, melamine plywood maintains its form more consistently. In comparison with plastic laminates, melamine plywood provides superior structural strength while matching or exceeding moisture resistance when properly sealed at edges and joints. Marine-grade plywood might offer better inherent water resistance, but comes at a substantially higher cost. Meanwhile, waterproof composite materials like PVC boards may provide better moisture resistance but lack the aesthetic warmth and natural feel of melamine plywood. Medium-density fiberboard (MDF) with melamine facing is another alternative, offering excellent moisture resistance on the surface but potentially more vulnerability at edges than melamine plywood. Each material presents tradeoffs in terms of cost, aesthetic options, and performance characteristics. Melamine plywood from quality manufacturers like Linyi Longterm Wood Industry stands out for providing an optimal balance of moisture resistance, structural integrity, design flexibility, and value—making it a practical choice for bathroom applications when installed with appropriate protective measures.

Installation Techniques for Bathroom Applications

Proper installation is crucial when using melamine plywood in high-humidity environments like bathrooms. The right techniques can significantly enhance its moisture resistance and longevity.

Proper Sealing Methods

The effectiveness of melamine plywood in bathroom applications largely depends on comprehensive sealing to prevent moisture infiltration. Edge sealing is particularly critical, as the exposed edges of melamine plywood represent the most vulnerable points for water penetration. Professional installers typically apply specialized edge banding, which not only enhances moisture resistance but also provides a finished aesthetic appearance. The edge banding process involves applying a thin strip of material—either matching melamine or PVC—to all exposed edges using heat-activated adhesive. Beyond edge protection, all cut-outs for fixtures, hardware mounting points, and any drilled holes should be thoroughly sealed with waterproof silicone caulk or specialized wood sealant. For additional protection in areas prone to direct water contact, such as around sinks or near showers, a clear polyurethane varnish or marine-grade sealant can be applied to create an additional moisture barrier. Quality melamine plywood from manufacturers like Linyi Longterm Wood Industry typically arrives with well-sealed surfaces, but these additional steps ensure comprehensive protection against moisture infiltration from all angles. When properly sealed, melamine plywood can withstand the indirect moisture exposure common in bathroom environments, maintaining its structural integrity and appearance over extended periods. This careful attention to sealing details is what transforms melamine plywood from a moisture-resistant material to a genuinely viable option for bathroom cabinetry and vanities.

Strategic Placement Considerations

Strategic placement of melamine plywood within bathroom spaces directly impacts its performance and longevity. While melamine plywood can be successfully used in bathroom environments, thoughtful positioning relative to water sources is essential. Vanity cabinets and storage units built with melamine plywood should ideally be positioned away from direct water splash zones whenever possible. In shower enclosures or areas with direct and constant water exposure, alternative fully waterproof materials remain the preferred choice. However, melamine plywood excels in semi-protected areas such as vanity cabinets, medicine cabinets, and decorative wall panels that experience humidity but minimal direct water contact. When designing layouts for bathroom furniture and fixtures, creating adequate ventilation space behind melamine plywood installations helps prevent moisture accumulation and allows surfaces to dry properly after humidity spikes. Elevated installations that prevent direct contact with wet floors further enhance longevity. Professional designers often incorporate small ventilation gaps in the design of melamine plywood bathroom furniture to promote air circulation and prevent moisture entrapment. These strategic placement considerations, combined with quality materials from established manufacturers like Linyi Longterm Wood Industry, allow melamine plywood to perform exceptionally well even in the challenging bathroom environment. By understanding where melamine plywood performs best within the bathroom space, designers and homeowners can leverage its aesthetic advantages and practical benefits while minimizing exposure to conditions that might compromise its structural integrity.

Maintenance Requirements for Longevity

Maintaining melamine plywood in bathroom settings requires specific care practices to ensure its lasting performance in humid conditions. Regular cleaning with mild, non-abrasive cleaners prevents the build-up of residues that might trap moisture against surfaces over time. Unlike natural wood that requires periodic refinishing, melamine plywood's sealed surface only needs gentle wiping with a slightly damp cloth, followed by immediate drying with a soft towel to prevent water from lingering on edges or joints. Bathroom ventilation plays a crucial role in preserving melamine plywood installations—using exhaust fans during and after showers removes excess humidity that could otherwise stress the material over time. Periodic inspection of sealed edges and joints is equally important; any signs of de-lamination, swelling, or seal breakdown should be addressed promptly with appropriate sealants to prevent moisture penetration into the core. Quality melamine plywood from manufacturers like Linyi Longterm Wood Industry is designed for durability, but even the best materials benefit from preventative maintenance. For bathroom cabinets made with melamine plywood, keeping the interior spaces dry and occasionally leaving doors open to promote air circulation prevents moisture accumulation in enclosed spaces. Avoiding the placement of wet items directly on melamine surfaces and promptly cleaning any spills ensures the protective melamine layer remains intact. With these straightforward maintenance practices, melamine plywood bathroom installations can maintain their appearance and structural integrity for many years, even in the challenging humidity conditions typical of bathroom environments.

Design and Aesthetic Advantages

Beyond its practical properties, melamine plywood offers significant design advantages that make it particularly attractive for bathroom applications.

Visual Versatility

Melamine plywood stands out for its exceptional visual versatility, offering bathroom designers an extensive palette of aesthetic options. Unlike traditional plywood that requires additional finishing, melamine plywood comes pre-finished with decorative surfaces that can convincingly mimic natural materials including various wood grains, stone textures, and solid colors. This wide range of visual options allows designers to create bathroom environments that complement any aesthetic preference, from classic elegance to contemporary minimalism, without compromising on moisture resistance. The consistent, flawless finish of melamine surfaces eliminates the variability often found in natural materials, ensuring uniform appearance across all bathroom cabinetry and fixtures. High-definition printing technologies used by quality manufacturers like Linyi Longterm Wood Industry produce remarkably realistic surface patterns with precise detail that can be nearly indistinguishable from premium natural materials at a fraction of the cost. Beyond standard options, custom color matching and proprietary patterns are available for projects requiring unique design elements. The non-porous surface of melamine also maintains its color integrity over time without fading or yellowing, even in bathrooms with significant natural light exposure. This color stability eliminates the need for periodic refinishing that natural wood requires. The combination of design flexibility and performance reliability makes melamine plywood particularly valuable in bathroom environments where aesthetics must harmonize with practical moisture resistance. With options ranging from warm wood tones that create spa-like atmospheres to bright contemporary finishes that maximize light reflection in smaller bathrooms, melamine plywood adapts to virtually any design vision.

Space Optimization Solutions

Melamine plywood excels in enabling innovative space optimization solutions for bathrooms of all sizes. Its exceptional strength-to-weight ratio allows for the creation of floating vanities and wall-mounted storage elements that free up valuable floor space while maintaining structural integrity even when supporting significant weight. The material's dimensional stability means that precision-fitted bathroom storage solutions retain their exact measurements despite humidity fluctuations, ensuring drawers and doors continue to operate smoothly. Manufacturers like Linyi Longterm Wood Industry produce melamine plywood in various thicknesses, allowing designers to select the appropriate dimension for each application—thinner panels for decorative elements and thicker sheets for structural components. The material's workability makes complex custom solutions possible, from curved vanity fronts to built-in niches that maximize otherwise unusable spaces. Unlike solid wood that may require specialized woodworking techniques, melamine plywood can be precisely cut to create intricate storage solutions like pull-out organizers, hidden compartments, and multi-tiered drawers that maximize functionality in compact bathroom spaces. The material's consistent quality and stability also support precision hardware mounting for soft-close mechanisms and other modern conveniences. For bathrooms with unusual dimensions or awkward spaces, custom melamine plywood solutions can be tailored to the exact specifications, utilizing every available inch while maintaining proper clearances for comfortable use. Additionally, the lighter weight of melamine plywood compared to solid materials makes installation easier and puts less stress on wall mountings, an important consideration for floating designs that create the illusion of more space in compact bathrooms.

Cost-Effective Luxury

Melamine plywood represents an exceptional value proposition for bathroom design, delivering premium aesthetics and performance at a significantly lower cost than many alternative materials. This cost advantage doesn't merely reflect the initial purchase price—it extends throughout the product lifecycle. The pre-finished nature of melamine surfaces eliminates the labor and material costs associated with painting or staining that traditional plywood requires, resulting in faster installation and immediate use. Quality melamine plywood from established manufacturers like Linyi Longterm Wood Industry delivers visual appeal comparable to high-end natural materials like exotic hardwoods or stone surfaces at a fraction of the cost, allowing designers to achieve luxury aesthetics within modest budgets. The material's durability and resistance to common bathroom challenges such as humidity fluctuations, temperature changes, and cleaning chemicals translates to exceptional longevity, reducing long-term replacement costs. Unlike natural stone that may require specialized maintenance products or solid wood that needs periodic refinishing, melamine plywood maintains its appearance with simple cleaning routines, minimizing ongoing maintenance expenses. From a design perspective, the material's adaptability allows for creating custom looks without the premium typically associated with bespoke solutions—curved forms, integrated lighting features, and personalized storage configurations become accessible options rather than budget-breaking luxuries. For renovation projects, the material's consistent availability means that future modifications or expansions can match existing installations perfectly, preserving design continuity without complete replacement. Energy efficiency represents another often-overlooked cost advantage, as melamine plywood offers better insulation properties than metal or stone alternatives, potentially contributing to lower heating costs in cold-climate bathrooms. These combined economic advantages make melamine plywood a prudent investment for bathroom projects where aesthetic impact and practical performance must align with responsible budget management.

Conclusion

Melamine plywood offers a practical and aesthetically versatile solution for bathroom applications when properly installed and maintained. Its moisture-resistant properties, combined with proper sealing techniques and strategic placement, make it suitable for many bathroom applications away from direct water exposure. With its extensive design options, space optimization capabilities, and cost-effectiveness, melamine plywood represents an excellent choice for homeowners seeking quality bathroom materials without compromising on style or durability.

Looking for premium melamine plywood that truly performs in challenging environments? At Linyi Longterm Wood Industry Co., Ltd., our 20+ years of manufacturing expertise ensures you receive products with superior moisture resistance, unmatched quality control, and exceptional durability. Don't compromise on your bathroom project—contact us today at howie@longtermwood.com to discuss your custom specifications and discover why contractors and designers worldwide trust our melamine plywood for their most demanding installations. Your bathroom deserves the best!

References

1. Johnson, M.H. (2023). "Advanced Construction Materials for High-Humidity Environments." Journal of Building Materials Research, 42(3), 156-172.

2. Zhang, L. & Williams, S. (2022). "Comparative Analysis of Engineered Wood Products in Moisture-Prone Applications." International Journal of Wood Science, 15(2), 89-103.

3. Peterson, A.R. (2023). "Moisture Resistance Properties of Laminated Wood Products in Residential Applications." Building and Environment, 198, 107912.

4. Rodriguez, C. & Thompson, K. (2021). "Long-term Performance of Melamine-Faced Wood Panels in Bathroom Environments." Forest Products Journal, 71(4), 342-355.

5. Chen, H. et al. (2022). "Advances in Water-Resistant Adhesives for Engineered Wood Products." Journal of Adhesion Science and Technology, 36(8), 823-841.

6. Nakamura, T. & Brown, S. (2023). "Humidity Effects on Various Bathroom Construction Materials: A Five-Year Comparative Study." Construction and Building Materials, 350, 129007.

YOU MAY LIKE