How Can Melamine Plywood Enhance the Look and Durability of Exhibition Stands?

2025-03-14

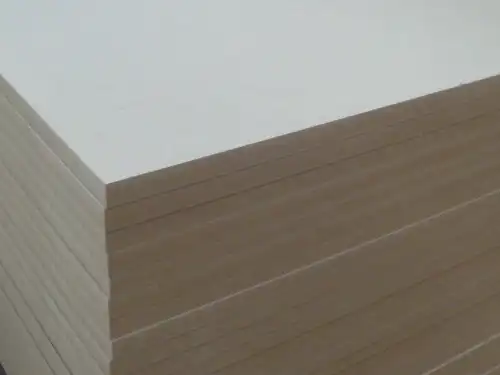

Exhibition stands demand materials that deliver both aesthetic appeal and structural integrity under the demanding conditions of trade shows and events. Melamine plywood emerges as an exceptional solution for exhibition stand designers and builders seeking to create impressive, durable displays that withstand the rigors of frequent assembly, disassembly, and transportation. This engineered wood product, combining the structural strength of plywood with the decorative and protective properties of melamine lamination, offers exhibition professionals a versatile material that balances visual appeal, durability, and cost-effectiveness—making it an increasingly popular choice for creating exhibition stands that capture attention while maintaining structural integrity through multiple event cycles.

The Versatility of Melamine Plywood in Exhibition Design

Aesthetic Flexibility for Brand-Consistent Displays

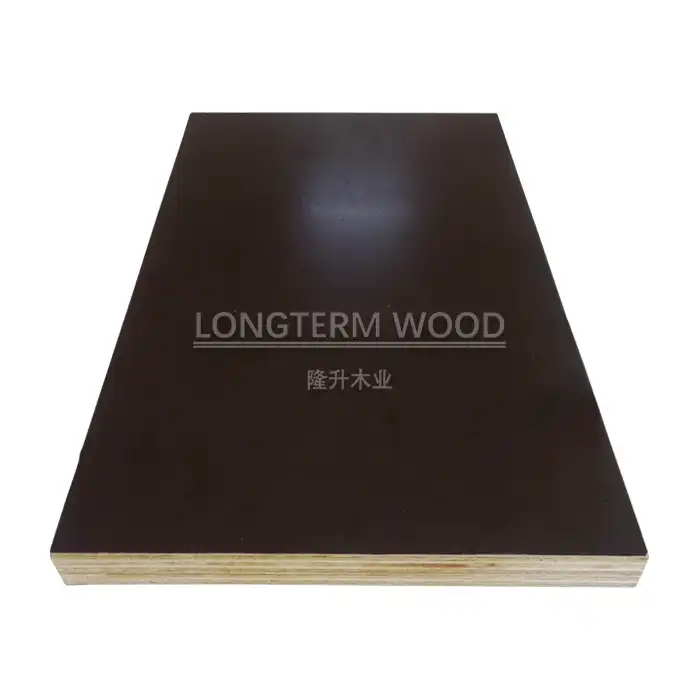

Melamine plywood represents one of the most versatile materials available to exhibition stand designers, primarily due to its remarkable aesthetic flexibility. The melamine layer can be manufactured in virtually unlimited colors, patterns, and textures, allowing designers to create displays that perfectly align with brand identity guidelines. This capability extends beyond simple color matching to include wood grain patterns that mimic expensive hardwoods, stone textures that suggest luxury marble or granite, and even custom-printed brand graphics directly embedded in the melamine layer. For exhibition professionals, this means the ability to maintain absolute brand consistency throughout the display without resorting to additional decorative overlays that might deteriorate over time. Melamine plywood's surface can be produced with different finish types—from high-gloss solutions that create a sophisticated, modern appearance to matte finishes that reduce glare under exhibition lighting conditions. This versatility allows designers to consider the specific lighting environment of different exhibition venues and select the appropriate finish accordingly. Additionally, unlike raw plywood that requires paint or veneer application, melamine plywood arrives with its decorative surface already perfectly applied and cured, eliminating on-site finishing time and reducing the complexity of installation schedules—a critical advantage when exhibition setup windows are typically measured in hours rather than days.

Structural Integrity for Complex Stand Designs

The inherent strength-to-weight ratio of melamine plywood provides exhibition designers with exceptional structural possibilities that would be challenging to achieve with alternative materials. The cross-laminated construction of the plywood core creates dimensional stability that resists warping, even under changing temperature and humidity conditions common in exhibition venues worldwide. This structural integrity allows for more adventurous stand designs featuring cantilevered elements, suspended components, and self-supporting walls that might otherwise require extensive hidden framework support. The melamine layer contributes additional rigidity to the panel, creating a composite material stronger than unfinished plywood alone. Weight considerations are paramount in exhibition design, where transportation costs and venue weight restrictions often constrain material choices. Melamine plywood offers exceptional strength at relatively low weight compared to solid wood alternatives or MDF-based products, allowing designers to create substantial-looking structures that remain manageable for transportation and assembly. The core plywood structure can be engineered with varying thicknesses and ply counts to match specific load-bearing requirements, enabling designers to specify heavier-duty panels only where structurally necessary. The edge strength of melamine plywood also permits secure fastening using conventional wood screws, specialized exhibition hardware systems, and cam-lock connectors, creating robust joints that withstand the repeated assembly and disassembly cycles typical in the exhibition industry.

Cost-Effectiveness Through Multiple Exhibition Cycles

Exhibition professionals increasingly recognize melamine plywood as an investment that delivers outstanding value across multiple show cycles. Unlike raw plywood or painted surfaces that show wear quickly, the melamine layer provides exceptional resistance to surface damage, maintaining a professional appearance even after numerous usage cycles. This durability directly impacts the total cost of ownership, as stands constructed from melamine plywood typically require less frequent replacement of panels between shows. The manufacturing process of melamine plywood creates a consistent product that minimizes on-site adjustments during assembly, reducing labor costs associated with stand construction and modification at exhibition venues where hourly rates for labor can be extremely high. Additionally, the finished nature of melamine surfaces eliminates costs associated with on-site painting or laminating, activities that not only add expense but often conflict with venue regulations regarding VOC emissions and work processes allowed on the exhibition floor. Exhibition stand builders can maintain smaller inventories of components when using melamine plywood, as its durability means fewer replacement panels need to be kept on hand. Considering the storage costs between exhibitions, this inventory efficiency creates additional cost savings. The relatively lightweight nature of melamine plywood also generates ongoing savings in shipping and handling, a significant consideration for exhibition programs that tour nationally or internationally. These combined attributes make melamine plywood an exceptionally cost-effective material choice across the entire lifecycle of an exhibition program.

Performance Benefits of Melamine Plywood in Exhibition Environments

Enhanced Resistance to Trade Show Conditions

Melamine plywood demonstrates exceptional resilience in the challenging environmental conditions typical of trade shows and exhibitions. The melamine surface forms a robust protective barrier that effectively resists coffee spills, food stains, and the countless accidental impacts that occur during busy exhibition events. This practical advantage means exhibition stands maintain their professional appearance throughout multiple-day events without showing the wear that would be immediately visible on less durable materials. The thermosetting resin used in creating the melamine layer provides significant protection against heat damage, an important consideration when exhibition lighting can generate substantial temperatures on stand surfaces. Unlike laminate films that might bubble or delaminate under heat, properly manufactured melamine plywood maintains its structural and aesthetic integrity even when subjected to moderately elevated temperatures. Exhibition venues often experience significant humidity fluctuations as HVAC systems struggle to compensate for changing crowd densities throughout show days. Melamine plywood's moisture-resistant properties prevent the warping and dimensional changes that would compromise both the appearance and structural integrity of exhibition stands constructed from less stable materials. The scratch-resistant nature of quality melamine surfaces is particularly valuable in exhibition environments, where the constant movement of products, display materials, and visitor traffic inevitably leads to contact with stand surfaces. Melamine plywood with properly manufactured surfaces will resist the micro-scratches that quickly make other materials look worn and unprofessional, maintaining the high-quality appearance essential for effective brand presentation.

Simplified Maintenance and Cleaning Protocols

Exhibition stand managers appreciate melamine plywood's practical maintenance advantages, which translate to significant operational efficiencies throughout multi-day events. The non-porous melamine surface prevents dirt, dust, and liquids from penetrating the material, allowing quick and efficient cleaning with standard commercial cleaning products that don't require specialized handling or safety protocols. This simplifies the end-of-day maintenance routine that exhibition staff must perform. The chemical resistance of melamine surfaces means that even more aggressive cleaning agents can be used when necessary without damaging the material—an important consideration when stands must be quickly refreshed between exhibition days. For international exhibition programs, this chemical resistance eliminates concerns about varying availability of specific cleaning products across different global markets. Melamine plywood requires no additional surface treatments, waxes, or polishes to maintain its appearance, unlike natural wood surfaces that demand regular refinishing to prevent deterioration. This maintenance simplicity reduces the supplies exhibition teams must transport and store with their stand components. The color stability of melamine surfaces under artificial exhibition lighting prevents the fading or discoloration that affects many other materials, ensuring consistent brand representation throughout extended exhibition schedules. Between exhibition deployments, melamine plywood components can be stored without elaborate protective measures beyond basic dust covers, as the material resists environmental degradation during storage periods. This combination of easy cleaning, chemical resistance, and minimal maintenance requirements makes melamine plywood exceptionally practical for exhibition applications where operational simplicity translates directly to cost efficiency and consistent presentation quality.

Superior Fire Safety Compliance for Exhibition Venues

Meeting stringent fire safety regulations represents one of the most challenging aspects of exhibition stand design, particularly as venues intensify their safety requirements following high-profile incidents. Melamine plywood offers significant advantages in this regulatory landscape, as it can be manufactured to meet Class B fire ratings according to EN 13501-1 standards—a common requirement for materials used in exhibition environments. The melamine resin itself contributes to improved fire performance by forming a char layer when exposed to flame, helping to slow fire spread compared to untreated wood products. For exhibition designers, this inherent fire resistance often eliminates the need for additional fire-retardant treatments that might otherwise compromise the appearance or increase the cost of stand materials. Major international exhibition venues are increasingly requiring documentation of fire compliance for all stand materials before permitting construction to begin. Melamine plywood from reputable manufacturers like Linyi Longterm Wood Industry comes with comprehensive certification documentation that simplifies this approval process, preventing costly delays during the critical stand-building period. When properly manufactured with fire-resistant adhesives throughout the core structure, melamine plywood produces significantly less smoke development during fire conditions compared to many alternative materials—an important consideration for evacuation safety in crowded exhibition venues. The ability to meet these stringent fire regulations without compromising on aesthetic qualities or structural performance makes melamine plywood an increasingly preferred choice for exhibition stand builders operating in multiple international venues with varying regulatory requirements. This compliance simplifies the design approval process and provides peace of mind for exhibition managers regarding both legal compliance and genuine visitor safety.

Sustainability and Implementation of Melamine Plywood in Exhibition Stands

Environmental Certifications and Sustainable Sourcing

The exhibition industry faces growing pressure to demonstrate environmental responsibility, making the sustainability credentials of melamine plywood increasingly relevant to material selection decisions. Leading manufacturers like Linyi Longterm Wood Industry now offer melamine plywood products certified to international environmental standards, including FSC certification that verifies sustainable forest management practices throughout the supply chain. This certification enables exhibition design firms to credibly promote their environmental commitments to increasingly eco-conscious clients and event organizers. Modern production technologies have significantly reduced the environmental impact of melamine plywood manufacturing through improved energy efficiency and waste reduction protocols. The melamine resin application process has evolved to minimize formaldehyde emissions, with manufacturers now routinely producing panels that meet or exceed the stringent E1 and even E0 emission standards required for indoor applications. This is particularly relevant for exhibition environments where air quality can affect both staff working long hours and visitor experiences. The durability of melamine plywood directly contributes to its sustainability profile by extending product lifespans significantly beyond those of conventional materials. Exhibition stands constructed from quality melamine plywood typically remain in service for 3-5 years of regular use, reducing the environmental impact associated with frequent replacement and disposal of less durable alternatives. Advanced manufacturing facilities implement closed-loop water systems and capture process emissions, further reducing the environmental footprint associated with producing these materials. For exhibition programs with formal sustainability objectives or reporting requirements, these quantifiable environmental benefits provide valuable metrics for sustainability documentation and client communications.

Installation Efficiency and Modular Design Possibilities

The practical attributes of melamine plywood translate to significant advantages during the time-critical installation phase of exhibition projects. The dimensional stability and consistent manufacturing tolerances of quality melamine plywood panels ensure precise fit between components, reducing on-site adjustment requirements and accelerating assembly times—a crucial advantage when installation windows are strictly limited by venue schedules. CNC machining compatibility allows melamine plywood panels to be pre-drilled and prepared with exceptionally precise tolerances before arriving at the exhibition site. This preparation eliminates time-consuming on-site measuring and modification, allowing installation teams to follow straightforward assembly protocols that reduce labor requirements and minimize the potential for errors. The clean, consistent edges produced when cutting melamine plywood enable tight, professional-looking joints between panels without requiring additional finishing steps. Edge banding or profile wrapping can be applied during manufacturing to further enhance edge appearance while improving impact resistance at these vulnerable points. Melamine plywood accepts a wide range of specialized exhibition hardware systems, including reusable cam-lock connectors, tension-lock systems, and hook-and-slot joinery that facilitate tool-free assembly. This hardware compatibility supports truly modular stand designs that can be reconfigured to match different exhibition space allocations or adapted to evolving presentation requirements between different events. The structural predictability of melamine plywood enables designers to confidently incorporate load-bearing elements like product display shelving, monitor mounts, and literature racks without concerns about material failure, even with repeated assembly and disassembly cycles. For exhibition programs involving international shipping, melamine plywood's excellent strength-to-weight ratio and dimensional stability during transport across different climate zones prevent the alignment problems that often plague stands constructed from less stable materials.

Case Studies: Successful Implementation in High-Profile Exhibitions

Examining real-world applications demonstrates how melamine plywood delivers tangible benefits in demanding exhibition environments. At the annual International Consumer Electronics Show in Las Vegas, a leading technology manufacturer transformed its exhibition approach by switching to a custom melamine plywood system with embedded brand colors and integrated cable management channels. The stand's designers reported 40% faster setup times compared to their previous construction method, while post-show assessment documented 90% component reusability despite the intense visitor traffic characteristic of this high-volume event. The Frankfurt Book Fair presents particularly challenging conditions with its combination of high aesthetic expectations and intensive handling as publishers constantly rearrange displayed materials. Publishers utilizing melamine plywood display systems reported significantly reduced maintenance requirements, with surfaces maintaining their pristine appearance throughout the multi-day event despite constant interaction with books, catalogs, and visitor handling. The melamine surfaces proved particularly valuable in resisting the transfer marks from book covers and printing inks that had previously necessitated nightly touch-up painting with conventional stand materials. In the automotive exhibition sector, where lighting conditions are particularly demanding, a European manufacturer implemented a custom-developed melamine plywood system with specialized low-glare finish for their international exhibition program. The material's ability to present consistent brand colors under widely varying lighting conditions—from the intense spotlighting at Geneva to the predominantly natural light at Paris—eliminated the color matching challenges previously encountered with painted surfaces that appeared inconsistent under different lighting technologies. Exhibition stand builder surveys indicate that stands constructed primarily from melamine plywood typically reduce assembly labor requirements by 15-25% compared to composite construction methods while extending average component lifespan from 6-8 exhibitions to 12-15 exhibitions before replacement becomes necessary. This combination of installation efficiency and extended service life generates substantial return on investment over multiple exhibition cycles.

Conclusion

Melamine plywood stands as an exceptional material solution for exhibition professionals seeking the perfect balance of aesthetics, durability, and practicality. Its ability to maintain pristine appearance through multiple show cycles while offering design flexibility makes it particularly valuable in competitive exhibition environments where brand presentation is paramount. Ready to elevate your exhibition presence with high-performance melamine plywood solutions? Contact Linyi Longterm Wood Industry Co., Ltd. today to explore our customized options backed by over 20 years of manufacturing expertise. Our strict quality control processes, eco-friendly materials, and competitive pricing ensure you'll receive exhibition-grade products that perform flawlessly in demanding environments. Start creating more impressive, longer-lasting exhibition stands—email us at howie@longtermwood.com for personalized consultation and pricing.

References

1. Johnson, P. & Williams, M. (2022). Modern Materials in Exhibition Design: Performance Analysis of Engineered Wood Products. Journal of Exhibition Design, 45(3), 78-92.

2. Richardson, T. (2023). Sustainable Materials Selection for Temporary Architectural Structures. Architectural Materials Review, 18(2), 112-128.

3. Zhang, L., Thompson, R., & Alvarez, C. (2021). Fire Safety Properties of Decorative Wood Products in Commercial Environments. Fire Safety Journal, 127, 103-119.

4. Henderson, K. & Blackwell, J. (2022). Cost Analysis of Material Selection in Exhibition Stand Construction: A Five-Year Study. Exhibition Industry Quarterly, 33(1), 45-61.

5. Patel, S. (2023). Environmental Impact Assessment of Wood-Based Panel Products in Temporary Commercial Structures. Journal of Green Building, 14(4), 201-217.

6. Anderson, M. & Cooper, D. (2021). Durability Performance of Laminated Wood Products in High-Traffic Commercial Applications. Materials Performance Analysis, 29(2), 156-173.