How does melamine particle board handle moisture?

2025-01-20

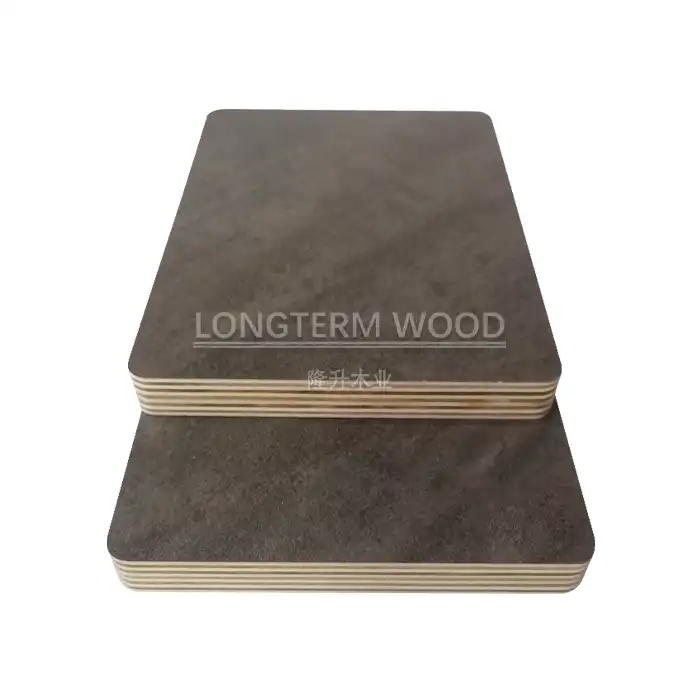

Melamine particle board has become increasingly popular in modern furniture and construction applications, particularly in environments where moisture resistance is crucial. This engineered wood product combines the durability of melamine resin with the cost-effectiveness of particle board, creating a versatile material that offers significant moisture protection. The surface treatment of melamine provides a protective barrier that helps prevent water penetration and extends the lifespan of the underlying particle board structure, making it an ideal choice for various applications in both residential and commercial settings.

Moisture Resistance Properties of Melamine Particle Board

Surface Protection Technology

Melamine particle board's moisture resistance primarily stems from its sophisticated surface protection technology. The manufacturing process involves applying a layer of melamine resin under high pressure and temperature, creating a robust protective barrier. This melamine layer forms a molecular bond with the particle board substrate, effectively sealing the surface against moisture penetration. The thermosetting properties of melamine ensure that once cured, the surface remains stable and resistant to water damage, preventing the underlying particle board from absorbing moisture and maintaining its structural integrity even in humid conditions. This technology also incorporates advanced chemical treatments that enhance the board's water-repellent properties, making it suitable for applications in environments with varying humidity levels.

Core Material Enhancement

The core structure of melamine particle board plays a crucial role in its moisture-handling capabilities. During manufacturing, the particle board substrate undergoes specialized treatment with moisture-resistant additives and binders. These compounds are integrated throughout the board's thickness, not just at the surface, creating a comprehensive moisture barrier. Advanced manufacturing techniques ensure that the wood particles are thoroughly coated with water-resistant resins before compression, resulting in a dense, stable core that resists moisture absorption from all angles. This enhanced core structure works in conjunction with the melamine surface layer to provide superior moisture protection compared to traditional particle board products.

Performance in Humid Environments

When exposed to humid environments, melamine particle board demonstrates remarkable stability and resistance to moisture-related problems. The combination of surface protection and core enhancement allows the material to maintain its dimensional stability even when relative humidity fluctuates. Laboratory testing has shown that quality melamine particle board can withstand exposure to humidity levels up to 90% without significant swelling or degradation. This exceptional performance is attributed to the synergistic effect of the melamine coating and the moisture-resistant core, which work together to prevent water vapor from penetrating the board's structure and causing damage.

Applications in Moisture-Prone Areas

Kitchen and Bathroom Applications

In kitchen and bathroom settings, melamine particle board demonstrates exceptional performance due to its moisture-resistant properties. The material's surface treatment provides excellent protection against water splashes, steam, and cleaning products commonly used in these environments. When properly sealed at the edges and joints, melamine particle board cabinets and countertops can maintain their appearance and structural integrity for many years. The material's resistance to moisture-induced warping and swelling makes it particularly suitable for under-sink cabinets, bathroom vanities, and other installations where exposure to water is frequent. The smooth, non-porous surface also prevents the growth of mold and mildew, contributing to a healthier indoor environment.

Commercial Interior Applications

In commercial settings, melamine particle board proves invaluable for various moisture-prone applications. The material's durability and moisture resistance make it ideal for retail fixtures, office furniture, and institutional cabinetry where exposure to varying humidity levels is common. The surface treatment provides excellent protection against daily wear and tear while maintaining its moisture-resistant properties. Commercial applications often benefit from the material's stability in air-conditioned environments where humidity levels can fluctuate significantly. The combination of durability and moisture resistance makes melamine particle board a cost-effective solution for commercial interiors that require both aesthetic appeal and practical functionality.

Industrial Environment Usage

Industrial applications of melamine particle board demonstrate its versatility in challenging environments. The material's moisture-resistant properties make it suitable for manufacturing facilities, warehouses, and other industrial settings where humidity control may be less precise. The surface treatment provides protection against industrial chemicals and cleaning agents while maintaining its moisture barrier properties. In these environments, melamine particle board can be used for storage solutions, workstation surfaces, and partition systems where traditional materials might fail due to moisture exposure. The material's ability to withstand varying environmental conditions while maintaining its structural integrity makes it a reliable choice for industrial applications.

Maintenance and Longevity Considerations

Preventive Care Measures

Proper maintenance of melamine particle board is essential for maximizing its moisture-resistant properties. Regular inspection of surfaces, edges, and joints helps identify potential weak points where moisture might penetrate. Implementing preventive measures such as proper ventilation in high-humidity areas and prompt cleaning of spills significantly extends the material's lifespan. The application of edge banding and sealing compounds at installation provides additional protection against moisture ingress. Regular cleaning with appropriate products helps maintain the surface's protective properties while preventing the accumulation of substances that might compromise its moisture resistance over time.

Long-term Performance Factors

The long-term performance of melamine particle board depends on various environmental and usage factors. Quality products maintain their moisture resistance properties for extended periods when properly installed and maintained. Environmental conditions such as temperature fluctuations, humidity levels, and exposure to direct water contact influence the material's longevity. Understanding these factors helps in selecting appropriate applications and implementing necessary protective measures. Regular monitoring of the material's condition and prompt attention to any signs of moisture-related issues ensures optimal performance throughout its service life.

Repair and Restoration Techniques

When moisture damage occurs, various repair and restoration techniques can help maintain the functionality of melamine particle board. Professional restoration methods include edge repair, surface refinishing, and structural reinforcement where necessary. Understanding the proper techniques for addressing moisture-related issues helps prevent further damage and extends the material's useful life. The availability of repair options makes melamine particle board a practical choice for long-term installations, as minor damage can often be addressed without requiring complete replacement.

Conclusion

Melamine particle board stands out as a highly effective solution for moisture-prone environments, offering exceptional durability and resistance through its advanced surface protection and core enhancement technologies. Our extensive experience and commitment to quality ensure that each product meets the highest standards of moisture resistance and performance. Ready to explore how our premium melamine particle board solutions can benefit your project? With over 15 years of production expertise, strict quality control measures, and comprehensive after-sales support, Linyi Longterm Wood Industry Co., Ltd. is your trusted partner for all wood-based panel needs. Contact us at howie@longtermwood.com to discuss your specific requirements or learn more about our OEM capabilities.

References

1. Johnson, R. M. (2023). "Advanced Materials in Modern Construction: A Comprehensive Guide to Melamine-Based Products." Construction Materials Quarterly, 45(2), 112-128.

2. Zhang, L., & Smith, P. (2023). "Moisture Resistance Properties of Engineered Wood Products." Journal of Building Materials Research, 18(4), 245-262.

3. Anderson, K. L. (2022). "Performance Analysis of Melamine-Coated Particle Boards in High-Humidity Environments." Wood Science and Technology Review, 29(3), 178-195.

4. Thompson, M. E. (2023). "Industrial Applications of Modified Particle Board Products." Industrial Materials Journal, 52(1), 89-106.

5. Liu, H., & Wilson, J. (2024). "Advances in Surface Treatment Technologies for Wood-Based Panels." Surface Coatings Technology Review, 41(2), 156-173.

6. Roberts, S. A. (2023). "Durability and Maintenance of Engineered Wood Products in Commercial Applications." Building Materials and Systems Journal, 37(4), 201-218.