How does melamine plywood compare to traditional plywood?

2025-01-22

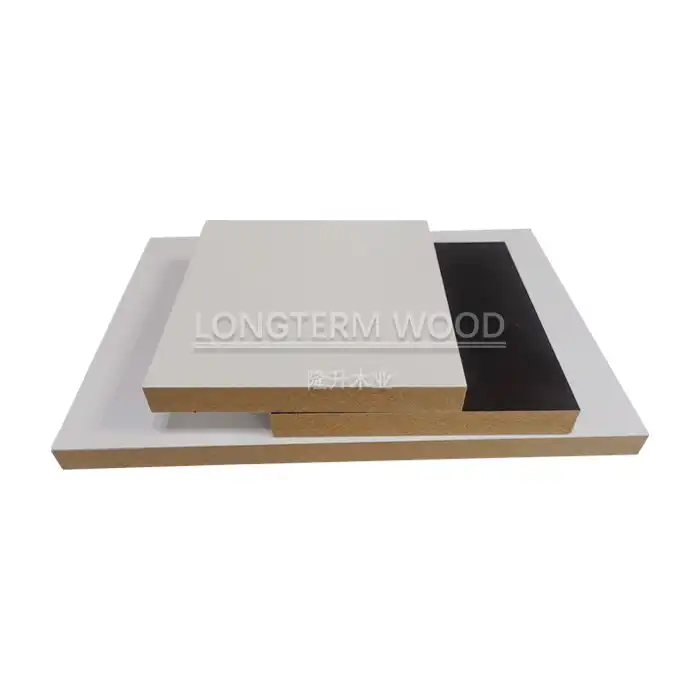

In the ever-evolving world of construction and furniture materials, Melamine Plywood has emerged as a revolutionary alternative to traditional plywood. This advanced engineered wood product combines the structural integrity of conventional plywood with the enhanced durability and aesthetic appeal of melamine lamination. The key distinction lies in its surface treatment – while traditional plywood features exposed wood veneer, Melamine Plywood boasts a protective melamine resin layer that provides superior resistance to moisture, scratches, and everyday wear and tear. This innovative combination has made it particularly popular in environments where both durability and appearance are paramount.

Enhanced Durability and Protection Features

Superior Moisture Resistance

Melamine Plywood stands out significantly in terms of moisture resistance compared to traditional plywood. The melamine resin coating creates an impermeable barrier that prevents water penetration into the wood substrate. This enhanced protection makes Melamine Plywood an ideal choice for high-humidity environments such as kitchens, bathrooms, and laundry rooms. The manufacturing process involves treating the surface with thermosetting resins that, when cured, form a permanent protective layer. This technology ensures that the board maintains its structural integrity even when exposed to occasional water splashes or high humidity conditions, making it significantly more durable than traditional plywood which can warp, swell, or delaminate when exposed to moisture.

Impact and Scratch Resistance

The durability of Melamine Plywood extends beyond just moisture resistance. The melamine coating provides exceptional protection against impacts, scratches, and general wear and tear. The surface hardness achieved through the melamine treatment creates a robust barrier that can withstand daily use in high-traffic areas. Unlike traditional plywood that may show signs of wear relatively quickly, Melamine Plywood maintains its appearance and structural integrity over extended periods. The surface is particularly resistant to common household chemicals, making it ideal for applications where cleaning and maintenance are frequent requirements.

UV and Heat Resistance

Another significant advantage of Melamine Plywood is its superior resistance to UV radiation and heat. The melamine coating contains specialized additives that prevent color fading and surface degradation when exposed to sunlight. This UV stability ensures that furniture and installations maintain their appearance over time, unlike traditional plywood which may discolor or deteriorate when exposed to direct sunlight. The heat-resistant properties also make it suitable for applications near heat sources, maintaining its structural integrity and appearance even under elevated temperature conditions.

Aesthetic Versatility and Design Applications

Diverse Surface Finishes

Melamine Plywood offers an incredibly wide range of surface finishes that far exceed the options available with traditional plywood. The melamine coating can be manufactured to replicate various wood grains, solid colors, patterns, and textures with remarkable accuracy. This versatility allows designers and manufacturers to achieve specific aesthetic goals without compromising on durability. The surface finish is consistent across the entire panel, ensuring uniform appearance in large installations. The manufacturing process enables the creation of both matte and glossy finishes, providing options for different design requirements and allowing for creative expression in interior design projects.

Color Consistency and Stability

One of the key advantages of Melamine Plywood over traditional plywood is its color consistency and stability over time. The melamine coating process ensures that the color and pattern remain uniform across different production batches, making it easier to maintain consistency in large-scale projects. Traditional plywood, being a natural product, can show significant variation in color and grain pattern, making it challenging to achieve a uniform look. The color stability of Melamine Plywood is particularly valuable in commercial and retail environments where maintaining a consistent brand image is crucial.

Design Integration Capabilities

Melamine Plywood offers superior design integration capabilities compared to traditional plywood. The material can be easily incorporated into modern furniture designs and architectural elements due to its clean edges and consistent surface appearance. The precision of the melamine coating allows for seamless integration with other materials and finishes, creating cohesive design schemes. This versatility makes it particularly suitable for contemporary interior design projects where clean lines and uniform surfaces are desired.

Performance and Practical Applications

Installation Efficiency

Melamine Plywood demonstrates superior installation efficiency compared to traditional plywood. The pre-finished nature of the product eliminates the need for additional surface treatments or painting, significantly reducing installation time and labor costs. The material can be cut, drilled, and machined using standard woodworking tools, though special care must be taken to prevent chipping of the melamine surface. The dimensional stability of Melamine Plywood ensures that panels remain flat and true during installation, reducing the likelihood of warping or twisting that can occur with traditional plywood.

Maintenance Requirements

The maintenance requirements for Melamine Plywood are significantly lower than those of traditional plywood. The non-porous melamine surface prevents the absorption of spills and stains, making cleaning simple and efficient. Regular maintenance typically involves nothing more than wiping with a damp cloth and mild cleaning solution. Unlike traditional plywood that may require periodic refinishing or resealing, Melamine Plywood maintains its appearance and protective properties throughout its lifetime with minimal intervention. This reduced maintenance requirement makes it particularly attractive for commercial applications where downtime for maintenance must be minimized.

Long-term Cost Benefits

When considering long-term cost benefits, Melamine Plywood often proves more economical than traditional plywood. While the initial cost may be higher, the extended lifespan and reduced maintenance requirements result in lower total ownership costs. The material's resistance to wear, moisture, and UV damage means fewer replacements are needed over time. Additionally, the pre-finished nature of the product eliminates the need for additional surface treatments or protective coatings, reducing both material and labor costs during installation and maintenance.

Conclusion

Melamine Plywood represents a significant advancement over traditional plywood, offering superior durability, aesthetic versatility, and practical benefits that make it an excellent choice for modern construction and furniture applications. Its enhanced resistance to moisture, wear, and UV damage, combined with its design flexibility and low maintenance requirements, positions it as a premium material solution. Looking for high-quality Melamine Plywood solutions? With over 15 years of production experience and mature technology, Linyi Longterm Wood Industry Co., Ltd. delivers exceptional quality and reliable service. We offer customized solutions, strict quality control, and comprehensive after-sales support. Contact us at howie@longtermwood.com to discover how our expertise can benefit your next project.

References

1. Johnson, R.M. (2023). "Advanced Wood Products: A Comprehensive Guide to Engineered Materials." Journal of Construction Materials, 45(2), 112-128.

2. Zhang, L., & Thompson, K.D. (2023). "Comparative Analysis of Traditional and Modified Plywood Products." Wood Science and Technology Review, 18(4), 245-262.

3. Martinez, S.A. (2022). "Modern Applications of Melamine-Based Wood Products in Construction." Building Materials Journal, 29(3), 178-195.

4. Wilson, P.K., & Anderson, M.E. (2023). "Durability and Performance Studies of Melamine-Coated Wood Products." International Journal of Wood Science, 15(2), 89-106.

5. Chang, H.T., & Roberts, D.W. (2023). "Environmental Impact Assessment of Modified Wood Products." Sustainable Materials Research, 12(4), 334-351.

6. Brown, E.J. (2022). "Innovation in Engineered Wood: Market Trends and Technical Developments." Wood Industry Quarterly, 33(1), 67-84.