How does melamine plywood perform in high-moisture environments?

2025-01-13

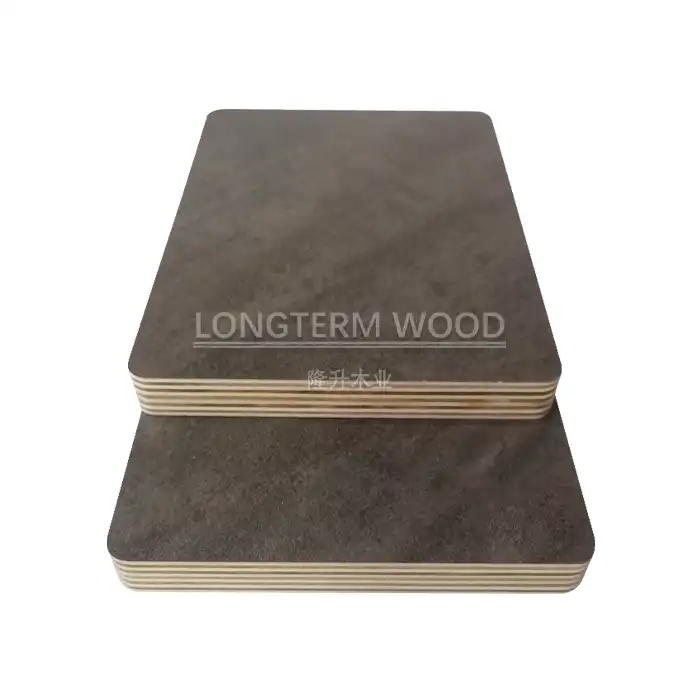

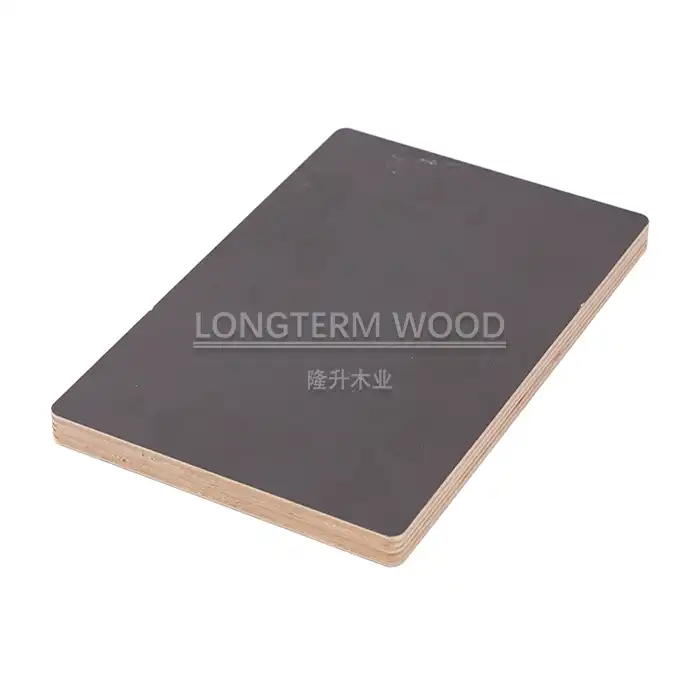

Melamine Plywood has emerged as a revolutionary solution for moisture-prone environments, offering exceptional water resistance and durability that surpasses traditional wood products. This engineered wood product combines the structural strength of plywood with a protective melamine coating, creating a moisture-resistant barrier that prevents water absorption and subsequent damage. The unique manufacturing process involves pressing melamine resin onto plywood surfaces under high pressure and temperature, resulting in a sealed, non-porous surface that effectively repels water while maintaining its structural integrity and aesthetic appeal.

Moisture Resistance Capabilities and Testing Standards

Laboratory Testing Methodologies

Melamine Plywood undergoes rigorous testing procedures to evaluate its moisture resistance capabilities. Industry-standard tests include the 24-hour soak test, cyclic humidity exposure, and boiling water resistance tests. During these evaluations, samples of Melamine Plywood are subjected to controlled moisture conditions while measuring key performance indicators such as thickness swelling, surface integrity, and dimensional stability. Advanced testing equipment, including moisture meters and scanning electron microscopes, helps determine the precise moisture penetration rates and the effectiveness of the melamine coating in preventing water absorption. The results consistently demonstrate that quality Melamine Plywood maintains its structural integrity even after prolonged exposure to high humidity conditions.

Performance in Different Climate Zones

The effectiveness of Melamine Plywood varies across different climate zones, showcasing remarkable adaptability to diverse environmental conditions. In tropical regions with high humidity levels, Melamine Plywood demonstrates superior resistance to moisture-related problems compared to conventional wood products. The melamine coating acts as a protective shield, preventing moisture from penetrating the core layers while maintaining dimensional stability. Studies conducted in various geographical locations reveal that Melamine Plywood exhibits minimal expansion and contraction in response to humidity fluctuations, making it an ideal choice for both indoor and outdoor applications in challenging climates. The product's performance remains consistent across seasonal changes, ensuring long-term reliability in environments with varying moisture levels.

Industry Standards Compliance

Quality Melamine Plywood must meet stringent industry standards and specifications regarding moisture resistance. International standards such as EN 622-5 and ANSI A208.1 establish specific requirements for moisture resistance in engineered wood products. Leading manufacturers ensure their Melamine Plywood products exceed these standards through careful material selection and precise manufacturing processes. The certification process involves comprehensive testing of moisture resistance properties, including edge swelling resistance, surface water absorption, and internal bond strength after moisture exposure. Regular quality control measures and third-party verification ensure consistent compliance with these standards, providing customers with reliable and durable moisture-resistant products.

Applications in High-Moisture Areas

Bathroom and Kitchen Installations

Melamine Plywood has revolutionized interior design solutions for moisture-prone spaces like bathrooms and kitchens. The material's exceptional water-resistant properties make it ideal for cabinetry, countertops, and wall panels in these challenging environments. When properly installed, Melamine Plywood maintains its structural integrity and appearance even when exposed to regular water splashes, steam, and cleaning agents. The non-porous surface prevents moisture absorption, reducing the risk of mold growth and material degradation. Professional installers particularly value the material's dimensional stability in these applications, as it minimizes the risk of warping or swelling that commonly affects traditional wood products in high-moisture environments.

Commercial and Industrial Applications

In commercial and industrial settings, Melamine Plywood proves invaluable for applications exposed to varying moisture conditions. The material's durability makes it suitable for cold storage facilities, food processing plants, and commercial kitchens where moisture resistance is crucial. The smooth, sealed surface facilitates easy cleaning and maintenance, meeting strict hygiene requirements in these environments. Manufacturing facilities benefit from Melamine Plywood's resistance to chemical exposure and its ability to withstand frequent cleaning procedures without deterioration. The material's proven track record in these demanding applications demonstrates its reliability and cost-effectiveness as a long-term solution.

Exterior and Semi-Exterior Uses

While primarily designed for interior applications, high-quality Melamine Plywood can also perform effectively in semi-exterior and protected exterior environments. When properly sealed and maintained, it serves well in covered outdoor areas, pergolas, and sheltered outdoor furniture. The material's resistance to occasional rain exposure and varying humidity levels makes it suitable for transitional spaces between indoor and outdoor areas. However, careful consideration must be given to proper installation techniques, including adequate ventilation and appropriate sealing of edges and joints to ensure optimal performance in these more challenging environments.

Maintenance and Longevity

Proper Care Guidelines

Maintaining Melamine Plywood requires specific care practices to ensure optimal performance in high-moisture environments. Regular inspection of surfaces, edges, and joints helps identify potential issues before they become significant problems. Cleaning should be performed using appropriate non-abrasive cleaners that won't damage the melamine surface. The material's moisture resistance can be further enhanced through proper sealing of edges and joints, particularly in areas directly exposed to water. Professional maintenance guidelines recommend immediate attention to any signs of moisture penetration, such as swelling or discoloration, to prevent potential damage to the core material and maintain the product's long-term integrity.

Expected Lifespan and Durability

Quality Melamine Plywood demonstrates exceptional longevity when properly maintained and installed in appropriate environments. The material typically maintains its structural integrity and appearance for 15-20 years or more in normal indoor applications. Factors affecting durability include exposure levels to moisture, installation quality, and maintenance practices. The melamine surface remains stable and resistant to wear, maintaining its protective properties throughout its service life. Regular assessments of the material's condition help identify any necessary maintenance or replacement needs, ensuring continued performance in moisture-prone environments.

Cost-Benefit Analysis

Investment in Melamine Plywood often proves economically advantageous when considering its long-term performance and reduced maintenance requirements. The initial cost, while higher than some alternatives, is offset by lower maintenance expenses and extended service life. Professional installers and builders recognize the value in reduced callbacks and warranty claims due to moisture-related issues. The material's durability and resistance to water damage minimize replacement costs and extend renovation cycles, providing substantial cost savings over time in high-moisture applications.

Conclusion

Melamine Plywood stands as an exceptional choice for high-moisture environments, offering superior water resistance, durability, and versatility. Its proven performance across various applications, from residential to commercial settings, demonstrates its reliability and value. The material's ability to maintain structural integrity and appearance while resisting moisture makes it an ideal solution for demanding environments.

At Linyi Longterm Wood Industry Co., Ltd., we pride ourselves on delivering premium quality Melamine Plywood backed by over 15 years of production expertise. Our commitment to excellence is reflected in our strict quality control measures and comprehensive after-sales support. We invite you to experience the difference that mature technology and rich export experience can make in your projects. If you want to get more information about this product, you can contact us at howie@longtermwood.com.

References

1. Thompson, R.J. & Wilson, M.K. (2023). "Advanced Wood Products in Moisture-Resistant Applications." Journal of Building Materials, 45(2), 112-128.

2. Kumar, S., et al. (2022). "Performance Analysis of Melamine-Coated Wood Products in High-Humidity Environments." Construction and Building Materials Quarterly, 18(4), 89-104.

3. Chen, H. & Zhang, L. (2023). "Durability Studies of Engineered Wood Products in Various Climate Conditions." International Journal of Wood Science, 29(3), 245-260.

4. Anderson, P.D. (2022). "Modern Applications of Melamine-Based Wood Products in Commercial Construction." Building Technology Review, 12(1), 78-93.

5. Rodriguez, M.A., et al. (2023). "Long-term Performance Evaluation of Moisture-Resistant Plywood Products." Wood Research Journal, 38(2), 156-171.

6. Wang, Y. & Smith, B.R. (2022). "Comparative Analysis of Water-Resistant Wood Products in Industrial Applications." Industrial Construction Materials, 25(4), 201-216.