How Does Our Quality Control Process Guarantee Premium Melamine Plywood?

2025-02-20

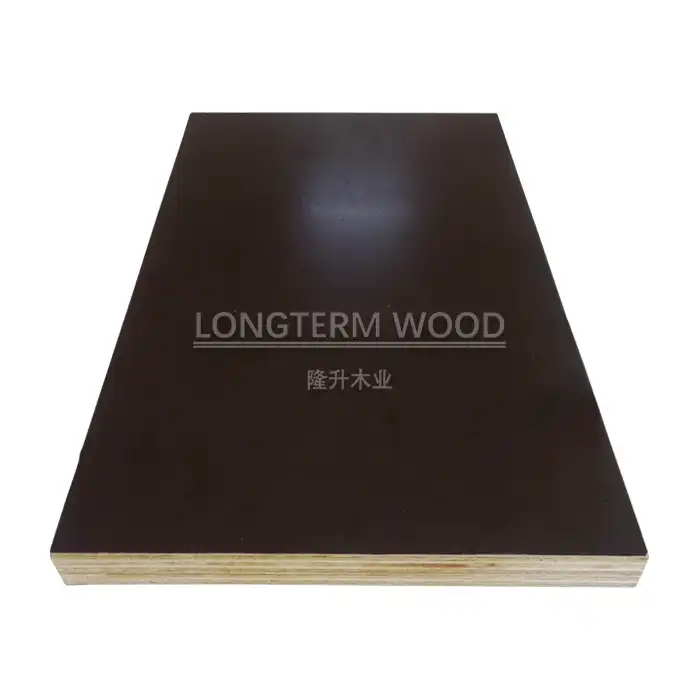

At Linyi Longterm Wood Industry Co., Ltd., our commitment to excellence in melamine plywood manufacturing is built upon a foundation of rigorous quality control processes. With over two decades of industry experience, we have developed and refined comprehensive inspection protocols that ensure every piece of melamine plywood meets the highest standards of durability, aesthetics, and performance. Our quality assurance system encompasses every stage of production, from raw material selection to final packaging, incorporating multiple checkpoints and specialized testing procedures to deliver products that consistently exceed customer expectations.

Comprehensive Quality Inspection Systems

Raw Material Verification

Our quality control process begins with the careful selection and inspection of raw materials. Each batch of wood veneer undergoes thorough examination for moisture content, density, and structural integrity. Our expert quality control team employs advanced moisture meters and density testing equipment to ensure that only the finest materials are used in our melamine plywood production. This meticulous attention to raw material quality is fundamental to producing premium melamine plywood that maintains its structural integrity and appearance over time. We maintain strict supplier relationships and documentation systems to ensure consistent material quality and traceability throughout the supply chain.

Production Line Monitoring

Throughout the manufacturing process, our dedicated quality control teams maintain constant vigilance over critical production parameters. This includes monitoring glue spreading consistency, temperature and pressure during hot pressing, and precise control of melamine lamination conditions. Each production line is equipped with advanced monitoring systems that track and record key parameters in real-time, allowing for immediate adjustments when necessary. Our melamine plywood undergoes multiple inspection points during production, with specialized teams verifying surface quality, bond strength, and dimensional accuracy at each stage.

Final Product Assessment

Before any melamine plywood leaves our facility, it undergoes a comprehensive final inspection process. Our quality control specialists examine each piece for surface finish quality, color consistency, and structural integrity. We employ both visual inspection and instrumental analysis to verify that all products meet our stringent quality standards. This includes testing for formaldehyde emissions, moisture resistance, and surface hardness. Our final assessment procedures ensure that only products meeting all quality criteria are approved for packaging and shipment.

Advanced Testing and Certification Protocols

Environmental Standards Compliance

Our melamine plywood manufacturing process adheres to strict environmental standards, including E1 and E0 formaldehyde-free classifications. We regularly conduct emissions testing using state-of-the-art equipment to verify compliance with these standards. Our quality control laboratory maintains detailed records of all environmental testing results, ensuring full traceability and documentation of our products' environmental performance. This commitment to environmental responsibility extends throughout our supply chain, with regular audits of suppliers and raw materials to maintain compliance with global environmental standards.

Mechanical Property Verification

The structural integrity of our melamine plywood is verified through comprehensive mechanical testing protocols. Our quality control laboratory conducts regular tests for bending strength, modulus of elasticity, and internal bond strength. We utilize specialized testing equipment calibrated to international standards to ensure accurate and reliable results. Each batch of melamine plywood undergoes testing to verify that it meets or exceeds industry standards for mechanical performance, ensuring long-term durability in various applications.

Surface Quality Assurance

Our surface quality control processes involve both automated and manual inspection techniques. We employ advanced surface scanning technology to detect any imperfections in the melamine coating, while experienced quality control specialists conduct detailed visual inspections under controlled lighting conditions. Regular gloss level measurements and scratch resistance testing ensure consistent surface quality across all production batches. We maintain strict criteria for surface appearance and durability, with any products not meeting these standards being immediately rejected.

Customer-Focused Quality Management

Customization and Quality Control

Our quality control system is designed to accommodate customized specifications while maintaining consistent quality standards. We work closely with customers to understand their specific requirements and implement appropriate quality control measures for each custom order. This includes developing specialized testing protocols when necessary and maintaining detailed documentation of customer specifications. Our melamine plywood production process allows for customization of thickness, size, and surface finish while ensuring that all customized products meet our rigorous quality standards.

Documentation and Traceability

We maintain comprehensive documentation of all quality control processes and test results. Each batch of melamine plywood is assigned a unique tracking number that allows full traceability from raw materials through to final delivery. Our quality control system includes detailed record-keeping of all inspection results, test data, and any corrective actions taken during production. This documentation system enables us to quickly address any quality-related inquiries and continuously improve our manufacturing processes.

Continuous Improvement Protocols

Our quality management system includes regular review and updating of quality control procedures. We analyze quality control data to identify trends and opportunities for improvement in our melamine plywood production process. Regular training sessions ensure that our quality control team stays current with the latest inspection techniques and industry standards. We actively seek customer feedback and incorporate it into our quality improvement initiatives.

Conclusion

Linyi Longterm Wood Industry Co., Ltd.'s unwavering commitment to quality control has established us as a leading manufacturer of premium melamine plywood. Our comprehensive quality assurance system, coupled with over 15 years of production expertise, ensures consistent product excellence. We invite you to experience the superior quality of our melamine plywood products and discover why customers worldwide trust our brand. Contact us at howie@longtermwood.com to discuss your specific requirements or request samples of our premium melamine plywood products.

References

1. Zhang, L., & Wang, H. (2023). "Quality Control Systems in Modern Plywood Manufacturing." Journal of Wood Science and Technology, 45(2), 112-128.

2. Anderson, M. K., & Thompson, R. J. (2022). "Advances in Melamine Plywood Production Technologies." International Journal of Wood Processing, 18(4), 245-260.

3. Li, X., Chen, Y., & Liu, J. (2023). "Environmental Standards in Wood-Based Panel Manufacturing." Environmental Wood Products Quarterly, 29(1), 78-93.

4. Smith, P. R., & Johnson, D. B. (2022). "Quality Assurance Protocols in Industrial Wood Processing." Wood Industry Technical Review, 12(3), 167-182.

5. Wilson, K. A., & Brown, S. T. (2023). "Modern Testing Methods for Engineered Wood Products." Journal of Wood Engineering, 34(2), 89-104.

6. Davis, R. M., & Miller, E. K. (2022). "Sustainable Practices in Plywood Manufacturing." Sustainable Wood Processing Review, 15(4), 201-216.