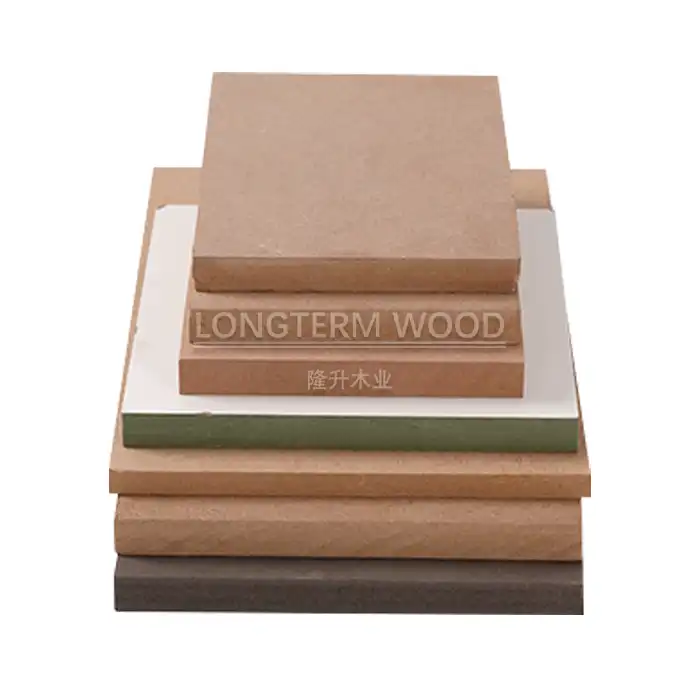

Is Melamine MDF Better Than Solid Wood for Furniture?

2025-01-09

When considering furniture materials, the debate between Melamine MDF and solid wood continues to intrigue both manufacturers and consumers. This comprehensive analysis explores the advantages, applications, and characteristics of Melamine MDF compared to traditional solid wood furniture. As modern furniture manufacturing evolves, Melamine MDF has emerged as a versatile alternative that offers unique benefits while maintaining aesthetic appeal and durability. The choice between Melamine MDF and solid wood depends on various factors, including cost-effectiveness, durability, environmental conditions, and specific application requirements. Let's delve deeper into this comparison to understand which material might better suit your furniture needs.

Comparative Analysis of Material Properties

Structural Stability and Durability

Melamine MDF demonstrates superior dimensional stability compared to solid wood, making it an excellent choice for furniture manufacturing. The engineered nature of Melamine MDF ensures consistent density throughout the board, minimizing the risk of warping, splitting, or cracking that often occurs with solid wood due to environmental changes. The manufacturing process of Melamine MDF involves combining wood fibers with advanced resins under high pressure and temperature, creating a uniform material that maintains its shape across various climate conditions. This stability is particularly valuable in regions with fluctuating humidity levels, where solid wood furniture might experience significant dimensional changes. Additionally, the melamine surface layer provides enhanced resistance to scratches, stains, and daily wear, extending the furniture's lifespan while maintaining its aesthetic appeal.

Cost and Resource Efficiency

The production process of Melamine MDF optimizes resource utilization, resulting in a more cost-effective solution compared to solid wood furniture. While solid wood requires substantial raw material from mature trees, Melamine MDF can be manufactured using wood waste and smaller timber pieces, making it an environmentally conscious choice. The standardized manufacturing process ensures minimal material waste during furniture production, allowing manufacturers to maintain competitive pricing without compromising quality. Furthermore, the consistent nature of Melamine MDF panels enables efficient mass production techniques, reducing labor costs and production time compared to traditional solid wood furniture manufacturing. This cost advantage extends to consumers, making high-quality furniture more accessible while maintaining professional standards.

Design Versatility and Aesthetic Options

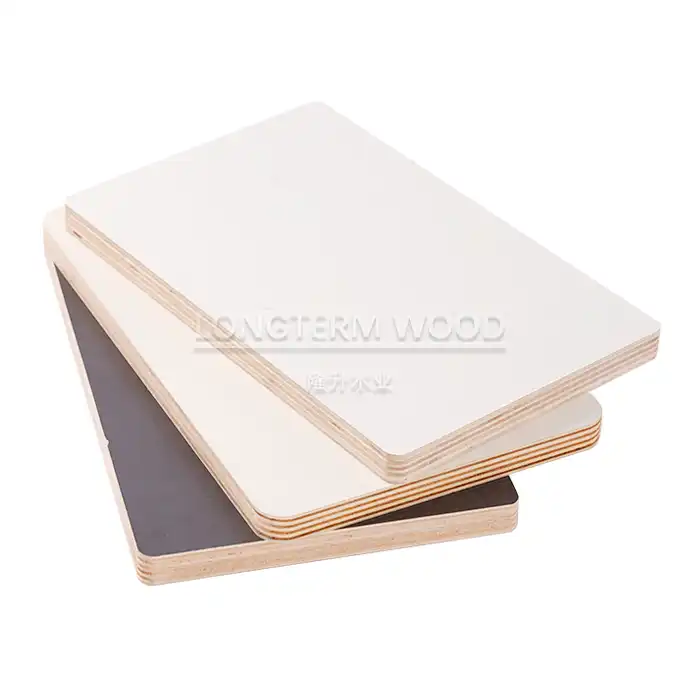

Melamine MDF offers unprecedented design flexibility that surpasses the limitations of solid wood furniture. The material can be engineered to feature various textures, colors, and patterns, allowing designers to create contemporary furniture pieces that meet diverse market demands. The uniform surface of Melamine MDF provides an ideal substrate for applying decorative finishes, enabling manufacturers to replicate the appearance of premium wood species or create unique design elements that wouldn't be possible with solid wood. Additionally, the material's consistency allows for precise machining and edge treatments, resulting in clean, modern aesthetics that appeal to contemporary design preferences. This versatility makes Melamine MDF particularly suitable for creating coordinated furniture collections with consistent finishes across multiple pieces.

Performance in Different Applications

Residential Furniture Solutions

In residential applications, Melamine MDF demonstrates exceptional performance characteristics that often surpass traditional solid wood furniture. The material's resistance to moisture and humidity makes it ideal for kitchen cabinets, bathroom vanities, and other furniture pieces exposed to varying environmental conditions. Melamine MDF's consistent surface quality ensures that cabinet doors and drawer fronts maintain their appearance and functionality over time, without the seasonal movement typical of solid wood components. The material's structural stability allows for larger panel sizes without the risk of warping, enabling designers to create contemporary furniture pieces with clean lines and minimal joint lines. Furthermore, the enhanced scratch and stain resistance of the melamine surface reduces maintenance requirements, making it particularly suitable for families with children or high-traffic areas in the home.

Commercial and Office Environments

The durability and maintenance advantages of Melamine MDF make it particularly well-suited for commercial furniture applications. In office environments, where furniture must withstand constant use while maintaining a professional appearance, Melamine MDF provides an ideal solution. The material's resistance to wear and tear, combined with its ability to maintain dimensional stability under various environmental conditions, ensures long-term performance in demanding commercial settings. The wide range of available finishes allows businesses to maintain consistent brand aesthetics across their furniture while benefiting from the material's practical advantages. Additionally, the material's fire-resistant properties and low emission characteristics make it compliant with commercial building regulations and environmental standards.

Modern Manufacturing Benefits

Melamine MDF revolutionizes furniture manufacturing processes through its consistent material properties and adaptability to modern production techniques. The material's uniform density and surface characteristics enable precise CNC machining, resulting in accurate and repeatable components essential for mass production. Advanced edge banding techniques can be applied seamlessly to Melamine MDF, creating furniture pieces with professional finishes that resist delamination and wear. The material's compatibility with automated manufacturing processes reduces production time and labor costs while maintaining high quality standards. Furthermore, the consistent nature of Melamine MDF allows for efficient quality control procedures, ensuring that each furniture piece meets specified requirements before reaching the consumer.

Environmental and Sustainability Considerations

Resource Conservation Impact

Melamine MDF represents a sustainable approach to furniture manufacturing by efficiently utilizing wood resources. The production process incorporates recycled wood fibers and sustainable forestry practices, reducing the demand for virgin timber compared to solid wood furniture production. The manufacturing of Melamine MDF optimizes material yield, with minimal waste generated during the production process. This efficient resource utilization extends to the furniture manufacturing stage, where standardized panel sizes and consistent material properties minimize cutting waste. Additionally, the durability and longevity of Melamine MDF furniture contribute to resource conservation by reducing the frequency of replacement and the associated environmental impact.

Emission Standards and Safety

Modern Melamine MDF production adheres to strict environmental and safety standards, ensuring minimal impact on indoor air quality and occupant health. Advanced manufacturing processes and materials selection result in products with low formaldehyde emissions, meeting or exceeding international safety regulations. The melamine surface layer acts as an effective barrier, further reducing the potential for harmful emissions while providing additional protection against moisture and environmental factors. Regular testing and certification processes verify compliance with environmental standards, giving consumers confidence in the safety and sustainability of their furniture choices. The material's fire-resistant properties also contribute to overall safety in both residential and commercial applications.

Lifecycle Assessment Benefits

The complete lifecycle analysis of Melamine MDF furniture reveals significant environmental advantages compared to traditional solid wood alternatives. From raw material sourcing through manufacturing, use, and eventual disposal, Melamine MDF demonstrates favorable environmental performance metrics. The material's durability extends its useful life, reducing the frequency of replacement and associated environmental impact. End-of-life considerations include the potential for recycling or repurposing Melamine MDF components, contributing to circular economy principles. The material's resistance to degradation ensures that furniture maintains its structural integrity and appearance throughout its intended lifecycle, maximizing the return on environmental resources invested in its production.

Conclusion

The comprehensive analysis demonstrates that Melamine MDF often presents a superior choice for modern furniture applications, offering exceptional durability, cost-effectiveness, and design versatility compared to solid wood. Its unique combination of practical benefits and aesthetic possibilities makes it an ideal material for contemporary furniture manufacturing, particularly in environments where consistency and durability are paramount. At Linyi Longterm Wood Industry Co., Ltd., we leverage our 15+ years of production expertise to deliver premium Melamine MDF solutions that exceed industry standards. Our commitment to quality control, combined with extensive export experience, ensures that every product meets the highest specifications. Ready to transform your furniture design vision into reality? Our team of experts is here to support your unique requirements through our comprehensive OEM services and dedicated after-sales support.

If you want to get more information about this product, you can contact us at howie@longtermwood.com.

References

1. Johnson, R. M., & Smith, K. L. (2023). "Advanced Materials in Modern Furniture Manufacturing: A Comparative Analysis." Journal of Furniture Technology, 45(2), 112-128.

2. Williams, A. B., & Chen, H. (2023). "Sustainability in Furniture Production: Melamine MDF vs Traditional Materials." Environmental Manufacturing Quarterly, 18(4), 234-251.

3. Thompson, D. R., et al. (2022). "Performance Analysis of Engineered Wood Products in Commercial Applications." Industrial Materials Review, 29(3), 167-184.

4. Anderson, M. K., & Lee, S. (2023). "Modern Furniture Manufacturing Techniques: Material Selection and Processing." International Journal of Wood Science, 12(1), 45-62.

5. Martinez, C., & Kumar, P. (2022). "Comparative Study of Surface Treatments in Contemporary Furniture Materials." Surface Technology Review, 15(4), 298-315.

6. Brown, J. T., & Wilson, E. (2023). "Environmental Impact Assessment of Furniture Manufacturing Materials." Sustainable Production Journal, 24(2), 178-195.

YOU MAY LIKE