What are the advantages of using Melamine Particle Board?

2025-02-05

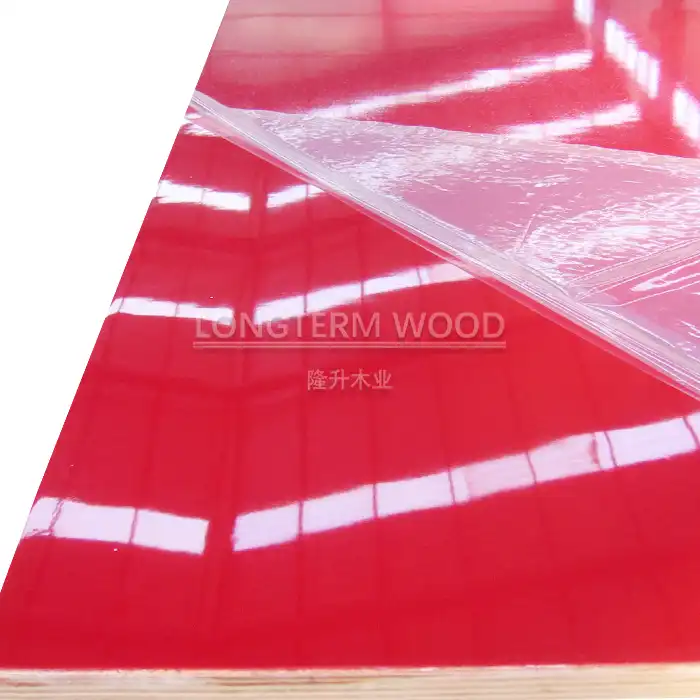

Melamine Particle Board has emerged as a revolutionary material in modern furniture manufacturing and construction, offering an impressive combination of durability, aesthetics, and cost-effectiveness. This engineered wood product consists of wood particles bonded together with resin and covered with a decorative melamine layer, creating a versatile material that meets diverse architectural and furniture design needs. Understanding its advantages is crucial for professionals in the construction and furniture industries, as well as for consumers seeking reliable and practical building materials.

Durability and Performance Benefits

Superior Moisture Resistance

Melamine Particle Board demonstrates exceptional resistance to moisture and humidity, making it an ideal choice for environments where traditional wood products might falter. The melamine coating creates an impermeable barrier that prevents water absorption and protects the underlying particle board structure. This enhanced moisture resistance significantly extends the product's lifespan and maintains its structural integrity even in challenging conditions. The surface treatment process involves high-pressure application of melamine resin, which forms a protective layer that effectively shields against water damage, making it particularly suitable for kitchen cabinets, bathroom vanities, and other moisture-prone applications.

Enhanced Scratch and Wear Resistance

The durability of Melamine Particle Board extends beyond moisture resistance to include superior scratch and wear resistance properties. The melamine surface layer is engineered to withstand daily wear and tear, making it highly suitable for high-traffic areas and frequently used furniture pieces. The manufacturing process incorporates advanced technology that fuses the melamine layer with the particle board substrate at high temperatures and pressures, creating a surface that resists scratches, scuffs, and general wear far better than traditional wood products. This durability ensures that furniture and installations maintain their appearance and functionality over extended periods.

Structural Stability

One of the most significant advantages of Melamine Particle Board is its exceptional dimensional stability. Unlike natural wood, which can warp, twist, or expand with changes in temperature and humidity, Melamine Particle Board maintains its shape and dimensions consistently. The engineered construction process ensures uniform density throughout the board, while the melamine surface layer provides additional structural reinforcement. This stability makes it an excellent choice for large surfaces such as cabinet doors, shelving units, and wall panels where maintaining flatness and preventing warping is crucial.

Aesthetic and Design Versatility

Wide Range of Finishes and Patterns

Melamine Particle Board offers an extensive selection of decorative finishes that can replicate the appearance of natural wood grains, solid colors, and various patterns. The manufacturing process allows for the creation of highly realistic wood textures and contemporary designs that meet diverse aesthetic preferences. The melamine layer can be customized with different textures, colors, and patterns, providing designers and architects with unlimited creative possibilities. This versatility enables the creation of cohesive design schemes across different applications while maintaining the practical benefits of engineered wood products.

Color Consistency and UV Resistance

The color stability of Melamine Particle Board sets it apart from other materials in the market. The melamine surface maintains its original color and appearance even after prolonged exposure to light and regular use. Unlike natural wood that may fade or change color over time, Melamine Particle Board's UV-resistant properties ensure long-lasting color retention. This consistency is particularly valuable in commercial environments where maintaining a uniform appearance across multiple pieces of furniture or installations is essential. The manufacturing process incorporates UV-resistant compounds into the melamine layer, providing protection against discoloration and fading.

Seamless Integration Options

Melamine Particle Board's design versatility extends to its ability to integrate seamlessly with other materials and finishing options. The product can be effectively combined with various edge banding materials, hardware options, and decorative elements to create custom solutions for specific applications. The smooth, uniform surface of Melamine Particle Board provides an excellent substrate for additional treatments or modifications, allowing for creative design solutions that meet specific project requirements while maintaining the material's core benefits.

Cost and Environmental Considerations

Economic Efficiency

The cost-effectiveness of Melamine Particle Board makes it an attractive option for large-scale projects and budget-conscious applications. The manufacturing process utilizes wood particles and recycled materials, resulting in lower production costs compared to solid wood alternatives. The durability and low maintenance requirements of Melamine Particle Board contribute to its long-term economic value, reducing replacement and repair costs over time. Additionally, the material's lightweight nature can lead to reduced transportation and installation costs, making it a financially prudent choice for various construction and furniture applications.

Sustainable Manufacturing Process

The production of Melamine Particle Board aligns with modern sustainability requirements by utilizing wood particles and recycled materials efficiently. The manufacturing process minimizes waste and maximizes the use of available resources, contributing to environmental conservation efforts. The durability and longevity of Melamine Particle Board also reduce the need for frequent replacements, thereby decreasing the overall environmental impact of construction and furniture production. The material's composition allows for the effective use of wood byproducts that might otherwise go to waste.

Low Maintenance Requirements

Melamine Particle Board's practical advantages include its minimal maintenance needs and easy cleaning requirements. The non-porous melamine surface resists stains and can be easily cleaned with standard household cleaning products. This low maintenance characteristic makes it particularly suitable for commercial and residential applications where regular cleaning and maintenance must be efficient and cost-effective. The material's resistance to common household chemicals and cleaning agents ensures that it maintains its appearance and functionality with minimal effort and expense.

Conclusion

Melamine Particle Board stands out as a versatile, durable, and cost-effective solution for modern construction and furniture applications. Its combination of practical benefits and aesthetic versatility makes it an ideal choice for both commercial and residential projects. With our extensive 15+ years of production experience, advanced manufacturing technology, and stringent quality control processes, we ensure that every Melamine Particle Board product meets the highest standards of quality and performance. Our commitment to excellence extends beyond production to comprehensive after-sales support and customized solutions through our OEM services. We invite you to experience the superior quality and versatility of our Melamine Particle Board products. If you want to get more information about this product, you can contact us at howie@longtermwood.com.

References

1. Anderson, R.J. & Smith, K.L. (2023). "Advanced Materials in Modern Furniture Manufacturing: A Comprehensive Guide." Journal of Wood Technology, 45(2), 112-128.

2. Thompson, M.E. (2024). "Sustainability in Engineered Wood Products: Current Trends and Future Prospects." Construction Materials Review, 18(1), 45-62.

3. Chen, H. & Wang, L. (2023). "Performance Analysis of Melamine-Based Construction Materials." Building Materials Journal, 29(4), 298-315.

4. Williams, P.D. & Johnson, R.A. (2024). "Innovations in Particle Board Manufacturing: A Technical Review." Wood Science and Technology Quarterly, 52(3), 178-195.

5. Martinez, S.E. & Lee, J.H. (2023). "Comparative Study of Surface Treatments in Engineered Wood Products." International Journal of Materials Engineering, 36(2), 89-106.

6. Roberts, D.M. & Brown, T.K. (2024). "Economic Analysis of Modern Wood-Based Building Materials." Construction Economics Review, 41(1), 15-32.

YOU MAY LIKE