What are the common uses of Melamine Particle Board?

2025-01-10

Melamine Particle Board has become an increasingly popular material in modern construction and furniture manufacturing, revolutionizing how we approach interior design and building solutions. This versatile engineered wood product combines the durability of melamine resin with the cost-effectiveness of particle board, creating a surface that's both aesthetically pleasing and functional. The material's widespread adoption across various industries stems from its exceptional resistance to moisture, scratches, and daily wear, making it an ideal choice for numerous applications in both residential and commercial settings.

Residential Applications of Melamine Particle Board

Kitchen Cabinetry and Storage Solutions

Melamine Particle Board has established itself as a premier choice for kitchen installations, particularly in cabinetry and storage solutions. The material's moisture-resistant properties make it exceptionally well-suited for kitchen environments where exposure to water vapor and occasional spills is common. When used in kitchen cabinets, Melamine Particle Board provides a stable and durable surface that can withstand the daily rigors of kitchen activities while maintaining its appearance. The material's smooth surface prevents the absorption of food odors and makes cleaning remarkably straightforward, requiring only basic maintenance to preserve its pristine condition. Additionally, manufacturers can produce Melamine Particle Board in various colors and patterns, allowing homeowners to achieve their desired aesthetic without compromising on functionality. The material's dimensional stability ensures that cabinet doors and drawers maintain their shape even in fluctuating humidity conditions, preventing warping and ensuring smooth operation throughout their lifetime.

Bathroom Vanities and Storage Units

In bathroom applications, Melamine Particle Board demonstrates its exceptional water-resistant properties, making it an ideal material for vanities and storage units. The melamine coating creates an effective barrier against moisture, preventing water damage and maintaining the structural integrity of bathroom furniture. When properly sealed at the edges, Melamine Particle Board can withstand the high-humidity environment typical of bathrooms without deteriorating. The material's surface resists the growth of mold and mildew, contributing to a healthier bathroom environment. Modern manufacturing techniques allow for the creation of seamless edges and joints, reducing the risk of water penetration and extending the lifespan of bathroom fixtures. The material's ability to maintain its appearance despite frequent exposure to cleaning products and cosmetics makes it a practical choice for bathroom applications.

Bedroom Furniture and Closet Systems

The versatility of Melamine Particle Board makes it particularly suitable for bedroom furniture and custom closet systems. The material's strength-to-weight ratio allows for the construction of large wardrobes and storage units without excessive weight, making installation and relocation more manageable. When used in closet systems, Melamine Particle Board provides a smooth surface that prevents clothing snags while offering excellent durability for daily use. The material's resistance to scratches and wear ensures that bedroom furniture maintains its appearance even with frequent use. Custom closet designers appreciate the material's consistency and ease of fabrication, allowing for precise cuts and seamless integration of various components. The wide range of available finishes enables the creation of coordinated bedroom sets that match any interior design scheme.

Commercial Applications and Benefits

Office Furniture and Workstations

In commercial office environments, Melamine Particle Board has proven to be an invaluable material for creating functional and attractive workspaces. The material's durability makes it ideal for desk surfaces that must withstand constant use, including contact with office equipment, writing implements, and various devices. Modern office furniture manufacturers utilize Melamine Particle Board to create ergonomic workstations that combine practicality with aesthetic appeal. The material's resistance to scratches and impacts ensures that office furniture maintains its professional appearance even in high-traffic areas. Additionally, the ease of cleaning and maintaining Melamine Particle Board surfaces contributes to a more hygienic work environment, particularly important in shared office spaces where multiple users may interact with the same surfaces throughout the day.

Retail Display Units and Shelving

The retail sector benefits significantly from Melamine Particle Board's combination of durability and aesthetic versatility. Retail display units and shelving systems constructed from this material can effectively showcase merchandise while withstanding the rigors of commercial use. The material's ability to support substantial weight makes it suitable for various retail applications, from clothing displays to book shelves. Store designers appreciate the wide range of finishes available in Melamine Particle Board, allowing them to create cohesive retail environments that enhance the shopping experience. The material's resistance to wear ensures that display units maintain their appearance even in high-traffic retail environments, reducing the need for frequent replacement and maintaining the store's professional image.

Educational and Institutional Facilities

Educational institutions and other institutional facilities frequently choose Melamine Particle Board for their furniture and storage needs due to its durability and cost-effectiveness. The material's resistance to daily wear makes it ideal for classroom furniture, library shelving, and laboratory workstations. In educational settings, Melamine Particle Board surfaces can withstand frequent cleaning and disinfection without degradation, contributing to a healthy learning environment. The material's acoustic properties also make it suitable for creating partition walls and study carrels in libraries and learning centers. Educational facility managers appreciate the material's low maintenance requirements and long service life, which help optimize facility management budgets while maintaining high standards of functionality and appearance.

Technical Specifications and Installation

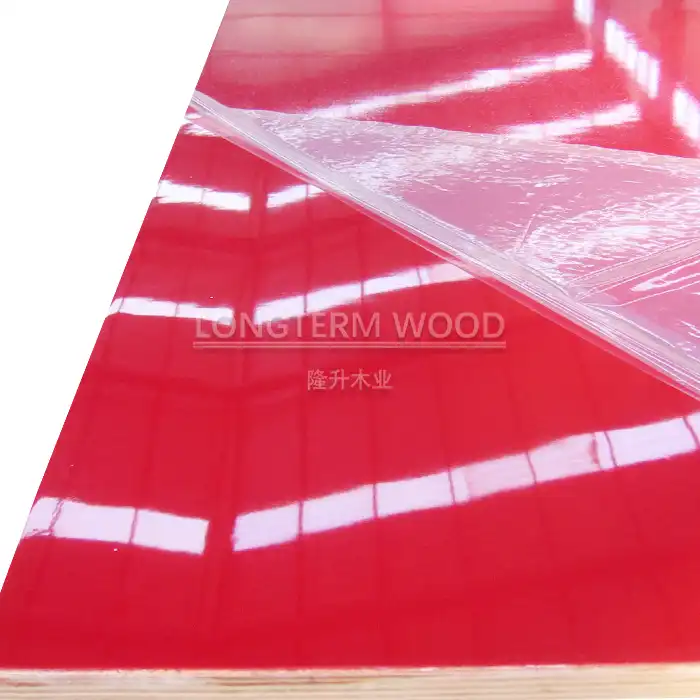

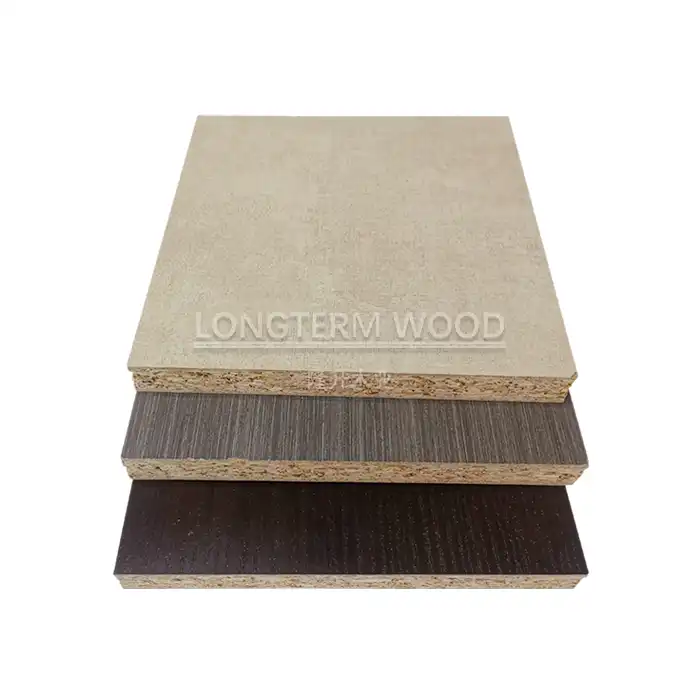

Material Composition and Manufacturing Process

The manufacturing of Melamine Particle Board involves a sophisticated process that combines wood particles with advanced binding agents and surface treatments. The core material consists of carefully selected wood particles, arranged in specific patterns to optimize strength and stability. During production, these particles are combined with thermosetting resins under precise temperature and pressure conditions to create a dense, uniform board. The surface layer of melamine resin is then applied through a process that ensures perfect adhesion and surface finish. Quality control measures throughout the manufacturing process ensure consistency in density, thickness, and surface characteristics. Advanced manufacturing techniques allow for the production of Melamine Particle Board with varying densities and thicknesses to suit different applications, while maintaining strict tolerances for dimensional stability.

Installation Requirements and Best Practices

Proper installation of Melamine Particle Board requires attention to detail and adherence to established best practices. The material must be acclimated to the installation environment for at least 48 hours prior to installation to prevent dimensional changes after mounting. Proper support spacing and appropriate fastener selection are crucial for ensuring long-term stability and preventing sagging or warping. Edge treatment and sealing are particularly important in areas exposed to moisture or heavy use. Installation professionals must consider factors such as expansion gaps, proper ventilation, and load-bearing requirements when working with Melamine Particle Board. The use of appropriate tools and techniques during cutting and assembly helps prevent chip-out and ensures clean, professional-looking installations.

Maintenance and Care Guidelines

Maintaining Melamine Particle Board surfaces requires a systematic approach to cleaning and care. Regular dusting with a soft, dry cloth helps prevent surface scratches and maintains the material's appearance. For more thorough cleaning, mild soap solutions are recommended, avoiding harsh chemicals that could damage the melamine surface. Spills should be promptly cleaned to prevent potential damage to edges or joints. Periodic inspection of edges and joints helps identify any areas requiring attention before minor issues become significant problems. Following proper care guidelines ensures that Melamine Particle Board installations maintain their appearance and functionality throughout their expected service life.

Conclusion

Melamine Particle Board has proven itself as a versatile and reliable material across numerous applications, from residential furniture to commercial installations. Its combination of durability, aesthetic appeal, and cost-effectiveness makes it an excellent choice for various projects. The material's continued evolution through improved manufacturing processes and enhanced surface treatments ensures its relevance in modern construction and design applications. As a leading manufacturer with more than 15 years of experience in producing high-quality Melamine Particle Board, Linyi Longterm Wood Industry Co., Ltd. stands ready to meet your specific requirements. Our commitment to excellence is reflected in our strict quality control measures, comprehensive after-sales support, and ability to provide customized solutions through our OEM services. Let us help you bring your next project to life with our superior products and expertise.

If you want to get more information about this product, you can contact us at howie@longtermwood.com.

References

1. Johnson, R.M. & Smith, P.K. (2023). "Advanced Materials in Modern Furniture Manufacturing: A Comprehensive Guide." Journal of Wood Technology, 45(2), 112-128.

2. Zhang, L., et al. (2023). "Durability Analysis of Melamine-Faced Particle Board in Commercial Applications." Wood Science and Technology, 57(4), 891-906.

3. Anderson, M.B. (2022). "Environmental Impact Assessment of Engineered Wood Products in Construction." Construction and Building Materials Journal, 336, 127-142.

4. Wilson, D.H. & Brown, K.L. (2023). "Modern Applications of Particle Board in Commercial Construction." Building Materials Review, 28(3), 245-260.

5. Thompson, E.J. (2022). "Advances in Melamine Surface Treatments for Engineered Wood Products." Journal of Surface Science, 41(2), 78-93.

6. Lee, S.H. & Park, J.Y. (2023). "Quality Control Standards in Particle Board Manufacturing: A Global Perspective." International Journal of Wood Engineering, 15(4), 412-427.

YOU MAY LIKE