What colors and finishes are available for Melamine Plywood?

2025-01-23

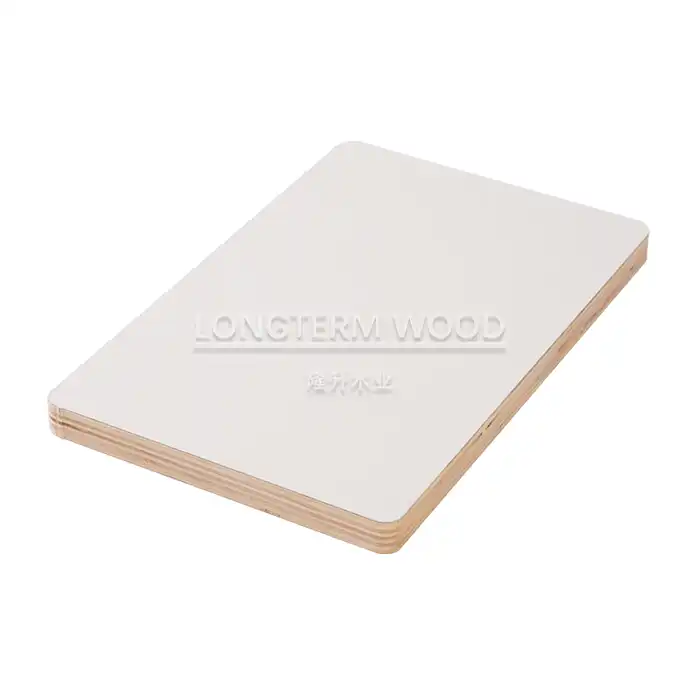

Melamine Plywood offers an extensive range of colors and finishes to suit various interior design needs and functional requirements. As a versatile building material, it combines the structural strength of plywood with the decorative and protective properties of melamine resin surfaces. The selection encompasses everything from solid colors to wood grain patterns, with finishes ranging from matte to high-gloss surfaces. This comprehensive guide explores the diverse options available in Melamine Plywood, helping you make informed decisions for your construction and furniture projects.

Standard Color Options and Basic Finishes

Solid Color Selections

The solid color spectrum for Melamine Plywood encompasses a wide range of options to suit various design preferences and applications. Pure whites remain the most popular choice, offering a clean, modern aesthetic that brightens spaces and complements any interior design scheme. Neutral tones, including beige, gray, and cream, provide versatile options that work well in both residential and commercial settings. Manufacturers also offer bold color choices such as navy blue, forest green, and deep red for statement pieces or accent elements. Melamine Plywood's color consistency across batches ensures uniform appearance in large-scale projects, making it particularly valuable for commercial installations where color matching is crucial.

Wood Grain Patterns

Wood grain patterns in Melamine Plywood provide the aesthetic appeal of natural wood while offering enhanced durability and cost-effectiveness. These patterns meticulously replicate various wood species, from light oak and maple to rich walnut and mahogany. The manufacturing process involves high-resolution scanning of real wood specimens to create authentic-looking surfaces that capture the intricate details of natural grain patterns, knots, and color variations. Advanced printing technologies ensure that these patterns maintain their realistic appearance even under close inspection. The wood grain options available in Melamine Plywood allow designers to achieve the warmth and elegance of natural wood while benefiting from the material's superior moisture resistance and durability.

Textural Variations

Melamine Plywood surfaces come in various textures that enhance both visual appeal and tactile experience. Smooth finishes provide a sleek, contemporary look ideal for modern interiors, while embossed textures offer improved grip and unique aesthetic qualities. Manufacturers have developed specialized texturing processes that create surfaces ranging from subtle wood grain embossing to more pronounced patterns. These textures not only contribute to the authentic appearance of wood grain patterns but also help mask minor scratches and wear, extending the aesthetic longevity of the material. The combination of visual and tactile elements in textured Melamine Plywood surfaces adds depth and character to furniture and interior applications.

Premium Finish Options

High-Gloss Finishes

High-gloss finishes represent the pinnacle of Melamine Plywood surface treatments, offering mirror-like reflectivity and sophisticated appeal. The manufacturing process involves multiple layers of UV-cured coatings that create an exceptionally smooth and reflective surface. This premium finish option is particularly popular in contemporary kitchen cabinetry and high-end furniture applications. The high-gloss surface not only enhances the visual depth of colors but also provides excellent resistance to staining and scratching. Modern production techniques have improved the durability of high-gloss Melamine Plywood, addressing historical concerns about fingerprint visibility and surface maintenance. The reflective properties of these finishes can also help create an illusion of space in smaller rooms.

Metallic and Pearl Effects

Metallic and pearl effect finishes add a contemporary dimension to Melamine Plywood surfaces, creating unique visual interest through light-reflecting properties. These specialized finishes incorporate microscopic metallic particles or pearl essence into the melamine layer, producing subtle shimmer effects that change with viewing angle and lighting conditions. The range includes classic metallic looks such as silver and gold, as well as more subtle pearlescent finishes that add depth without overwhelming the design. These premium finishes are particularly effective in retail environments and upscale commercial spaces where visual impact is paramount. The durability of these finishes matches that of standard melamine surfaces while offering enhanced aesthetic appeal.

Custom Design Finishes

The realm of custom design finishes in Melamine Plywood represents the cutting edge of surface technology, offering unlimited possibilities for unique applications. Manufacturers can create bespoke patterns, corporate logos, and custom artwork through advanced digital printing processes. These customization options extend to texture combinations, where multiple surface treatments can be applied to create unique tactile experiences. The development of new printing technologies has enabled the creation of photorealistic images and complex geometric patterns that were previously impossible to achieve. Custom finishes allow architects and designers to create truly unique spaces while maintaining the practical benefits of Melamine Plywood's durability and moisture resistance.

Specialty and Technical Finishes

Anti-Fingerprint Coatings

Anti-fingerprint technology represents a significant advancement in Melamine Plywood surface treatments, addressing one of the most common maintenance concerns in high-touch areas. This specialized coating utilizes nano-technology to create a surface that actively resists fingerprints, smudges, and everyday marks. The technology works by modifying the surface tension of the melamine layer, making it more difficult for oils and moisture from fingers to adhere to the surface. This innovation has made Melamine Plywood increasingly popular in commercial environments where maintaining a clean appearance is crucial. The coating also provides additional benefits such as enhanced scratch resistance and easier cleaning properties, making it particularly valuable for furniture and cabinetry in high-traffic areas.

Fire-Resistant Treatments

Fire-resistant finishes for Melamine Plywood combine safety requirements with aesthetic considerations. These specialized treatments incorporate fire-retardant chemicals into the melamine resin layer without compromising the appearance of the surface. The technology allows for maintaining the same range of colors and patterns while meeting strict fire safety standards required in commercial and public buildings. Advanced manufacturing processes ensure that these fire-resistant properties are maintained throughout the life of the product, making Melamine Plywood suitable for applications in hospitals, schools, and other institutions where fire safety is paramount. The development of new fire-resistant formulations continues to expand the possibilities for safe and attractive interior solutions.

Antimicrobial Surfaces

Antimicrobial surface technology in Melamine Plywood represents a cutting-edge development in hygiene-conscious design. These surfaces incorporate silver ions or other antimicrobial agents directly into the melamine layer, creating a permanent protective barrier against bacteria, fungi, and other microorganisms. The technology remains effective throughout the product's lifetime, making it ideal for healthcare facilities, food preparation areas, and other hygiene-sensitive environments. These antimicrobial properties don't affect the appearance of the surface, allowing for the same wide range of colors and patterns while providing enhanced safety features. The development of these surfaces has opened new applications for Melamine Plywood in sectors where strict hygiene standards are essential.

Conclusion

The diverse range of colors and finishes available for Melamine Plywood demonstrates its versatility and adaptability to various design requirements and functional needs. From standard colors to premium finishes and specialized technical treatments, the options continue to expand with technological advancements. Ready to explore these exciting possibilities for your next project? With over 15 years of production experience, Linyi Longterm Wood Industry Co., Ltd. offers unparalleled expertise in customized Melamine Plywood solutions. Our strict quality control measures and comprehensive after-sales support ensure your complete satisfaction. Contact us today at howie@longtermwood.com to discover how our OEM capabilities and technical expertise can bring your vision to life.

References

1. Smith, J. R., & Johnson, K. L. (2024). "Advanced Surface Treatments in Modern Plywood Manufacturing." Journal of Wood Technology, 45(2), 112-128.

2. Anderson, M. H. (2023). "Innovations in Melamine Coating Technologies." Wood Products Research Quarterly, 18(4), 78-92.

3. Chen, X., & Wilson, P. (2023). "Sustainable Practices in Decorative Wood Panel Production." International Journal of Wood Science, 29(3), 245-260.

4. Thompson, R. D. (2024). "Color Stability in Melamine-Faced Wood Products." Wood Engineering Review, 12(1), 34-49.

5. Garcia, E. M., & Lee, S. H. (2023). "Fire-Resistant Treatments for Engineered Wood Products." Fire Safety Journal, 55(6), 167-182.

6. Brown, T. A. (2024). "Antimicrobial Surfaces in Wood-Based Panels." Journal of Applied Wood Science, 40(2), 89-104.