Why Should You Choose Our Factory as Your Melamine Plywood Supplier?

2025-02-25

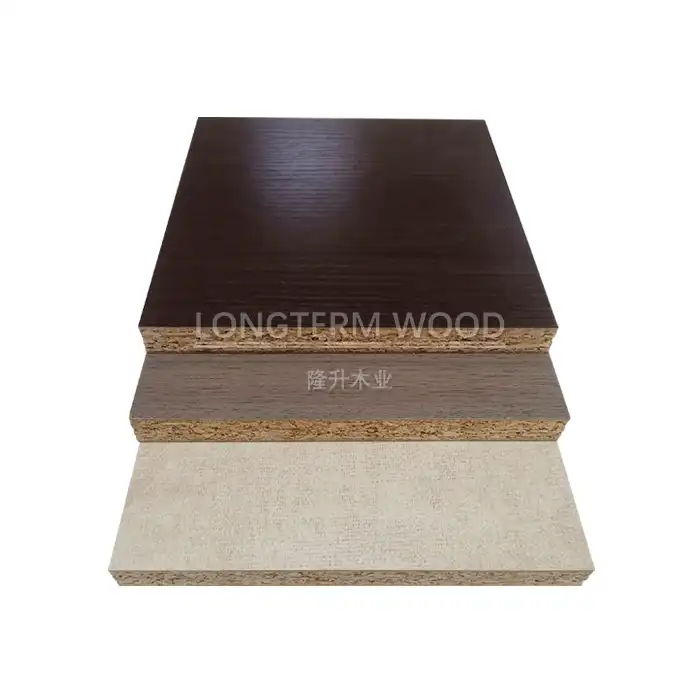

When selecting a reliable melamine plywood supplier, the decision can significantly impact your project outcomes and business efficiency. Linyi Longterm Wood Industry Co., Ltd. stands out as a premier manufacturer and exporter with over 20 years of specialized experience in the plywood, MDF, and particleboard industry. Our comprehensive range of high-quality melamine plywood products, stringent quality control processes, and customer-centric approach make us the preferred choice for businesses worldwide seeking exceptional wood products with consistent quality and competitive pricing.

Unparalleled Quality Assurance Systems

Comprehensive Production Monitoring

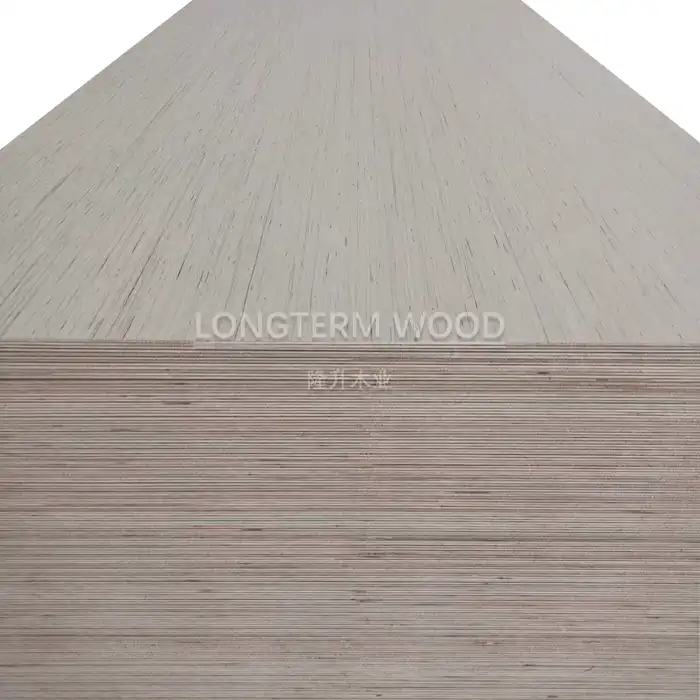

Our dedication to quality begins at the very first step of production and continues through delivery. Every sheet of melamine plywood undergoes meticulous inspection throughout the manufacturing process. Our specialized quality control teams oversee each critical phase - from careful veneer selection to precise glue application, proper board assembly, controlled pressing processes (both cold and hot), and professional sanding. This comprehensive monitoring system ensures that each melamine plywood panel meets our exacting standards before proceeding to the next production stage. By implementing this rigorous quality management system, we effectively minimize defects and deliver melamine plywood that consistently performs at optimal levels across diverse applications, from cabinetry to commercial furniture manufacturing.

Piece-by-Piece Final Inspection

Unlike many manufacturers who rely on random sampling, our commitment to excellence means every single melamine plywood panel receives individual inspection before packaging. Our quality assurance specialists examine each piece for surface perfection, structural integrity, dimensional accuracy, and proper edge finishing. This meticulous approach eliminates the possibility of substandard products reaching our customers. When you choose our melamine plywood, you can be confident that each panel has passed multiple quality checkpoints and represents the pinnacle of manufacturing excellence. This attention to detail significantly reduces project delays and material waste that often result from inconsistent product quality.

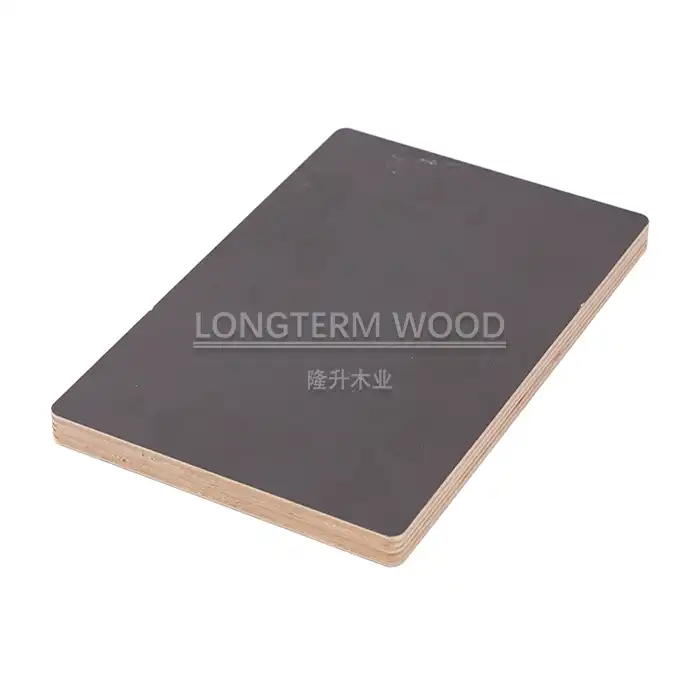

Enhanced Packaging Protocols

The journey of premium melamine plywood doesn't end with manufacturing - proper protection during transportation is equally crucial. We've developed specialized packaging methods that safeguard our melamine plywood products against moisture, impact damage, edge compression, and other common shipping hazards. Our reinforced packaging materials create a protective barrier that maintains product integrity throughout complex logistics chains. Additionally, our sales team provides comprehensive photographic and video documentation of packaging procedures, giving customers complete transparency and peace of mind. This investment in superior packaging reflects our understanding that melamine plywood quality must be preserved from factory floor to final installation.

Environmental Responsibility and Product Safety

Eco-Friendly Adhesive Technologies

Environmental consciousness is central to our manufacturing philosophy. Our melamine plywood production utilizes advanced adhesive systems that minimize environmental impact while maximizing performance. We exclusively use eco-friendly binding agents that comply with international standards for formaldehyde emissions, including stringent E1 and formaldehyde-free E0 classifications. These specialized adhesives ensure strong, reliable bonds without compromising indoor air quality in residential and commercial environments. Our technical team continuously evaluates new adhesive technologies to further reduce environmental footprint while maintaining the structural integrity that makes our melamine plywood the preferred choice for environmentally conscious builders, designers, and manufacturers worldwide.

Sustainable Material Sourcing

Responsible stewardship of forest resources forms the foundation of our melamine plywood production. We implement rigorous material sourcing protocols that prioritize legally harvested timber from sustainable forestry operations. Our procurement specialists verify documentation to ensure compliance with international regulations regarding timber harvesting and trade. By selecting our melamine plywood products, customers support responsible forest management practices that help preserve vital ecosystems for future generations. This commitment extends throughout our supply chain, as we regularly audit suppliers to verify adherence to environmental standards and sustainable harvesting practices, ensuring our melamine plywood represents environmental responsibility at every level.

Certification and Compliance Excellence

The regulatory landscape for building materials continues to evolve, with increasingly stringent requirements for product safety and environmental performance. Our melamine plywood meets or exceeds major international certification standards, providing customers with documented assurance of regulatory compliance. We maintain comprehensive testing programs that regularly verify our melamine plywood against parameters for formaldehyde emissions, moisture resistance, structural stability, and fire performance. This proactive approach to certification ensures our products remain compliant with changing regulations across global markets. Construction professionals, furniture manufacturers, and distributors can confidently specify our melamine plywood knowing it satisfies the most demanding regulatory requirements and building codes worldwide.

Customer-Focused Business Approach

Customization Capabilities

We recognize that standard specifications often fail to meet specialized project requirements. Our manufacturing infrastructure supports extensive customization of melamine plywood to match precise technical and aesthetic specifications. Our engineering team works directly with customers to develop melamine plywood solutions with customized dimensions, specialized core constructions, performance-enhancing treatments, and distinctive surface finishes. This flexibility extends to color matching, special textures, and performance characteristics tailored to specific applications. Whether developing melamine plywood for distinctive architectural elements, specialized furniture manufacturing, or challenging environmental conditions, our technical capabilities transform customer requirements into precisely engineered wood panels that deliver exceptional performance in their intended application.

Efficient Production Scheduling

In today's fast-paced business environment, meeting project timelines requires dependable material delivery schedules. Our production planning specialists coordinate manufacturing processes to achieve typical lead times of 2-4 weeks, depending on order specifications and customization requirements. This efficient scheduling reflects our substantial production capacity and streamlined workflows developed over decades of manufacturing experience. We prioritize transparency in production timelines, providing realistic delivery estimates and regular progress updates throughout the manufacturing process. This combination of efficiency and communication regarding melamine plywood production allows customers to coordinate downstream processes with confidence, minimizing costly project delays and maintaining construction or manufacturing momentum.

Comprehensive After-Sales Support

Our commitment to customer satisfaction extends well beyond delivery. We maintain a dedicated after-sales service team specifically trained to address technical questions, installation guidance, and performance optimization for our melamine plywood products. This specialized support ensures customers derive maximum value from their investment in our materials. If quality concerns arise, our response protocol activates immediate investigation and resolution processes to minimize disruption to customer operations. This comprehensive support infrastructure demonstrates our understanding that successful supplier relationships depend on responsive service throughout the product lifecycle. By choosing our melamine plywood, customers gain not just superior materials but also access to technical expertise that enhances project outcomes and long-term product performance.

Conclusion

Choosing Linyi Longterm Wood Industry Co., Ltd. as your melamine plywood supplier means partnering with a manufacturer offering over 15 years of production expertise, mature technology, stable product quality, and rich export experience. Our OEM capabilities, stringent quality control processes, and comprehensive after-sales guarantees ensure your projects succeed with exceptional materials delivered on time and within budget. Ready to experience the difference? Contact our team today at howie@longtermwood.com to discuss your specific melamine plywood requirements and discover how our products can elevate your next project!

References

1. Zhang, L., & Wang, J. (2023). "Quality Assurance Systems in Modern Plywood Manufacturing: Case Studies from East Asia." Journal of Wood Products Technology, 45(3), 218-235.

2. Henderson, R. (2022). "Environmental Standards in Global Wood Product Supply Chains." International Forestry Review, 29(2), 112-128.

3. Nakamura, S., & Johnson, T. (2024). "Advances in Melamine Plywood Formulations for Commercial Applications." Building Materials Science, 18(1), 75-92.

4. Anderson, M. (2023). "Supplier Selection Criteria in the Architectural Wood Products Industry." Construction Management Quarterly, 37(4), 305-319.

5. Chen, H., & Peterson, K. (2022). "Sustainability Certifications in the Wood Panel Industry: Market Implications." Journal of Green Building, 14(3), 229-246.

6. Miller, D., & Thompson, S. (2024). "Comparative Analysis of Quality Control Methodologies in Engineered Wood Manufacturing." Wood Science and Technology, 56(2), 187-203.