How durable is Melamine Particle Board?

2025-01-21

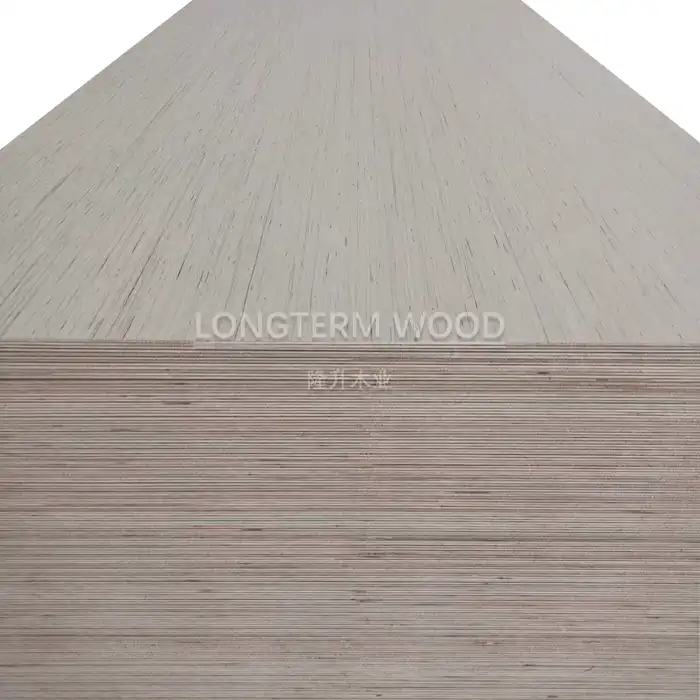

Melamine Particle Board has emerged as a revolutionary material in the furniture and construction industry, offering exceptional durability and versatility. This engineered wood product combines the structural integrity of particle board with a protective melamine resin surface, creating a robust material that stands up to daily wear and tear. The durability of Melamine Particle Board is attributed to its unique manufacturing process, where wood particles are compressed and bonded together under high pressure and temperature, then finished with a melamine resin coating that provides superior resistance to scratches, stains, and moisture.

Factors Influencing Melamine Particle Board Durability

Manufacturing Process Quality

The durability of Melamine Particle Board largely depends on the manufacturing process quality. At Linyi Longterm Wood Industry Co., Ltd., the production involves multiple precise steps that ensure optimal durability. The process begins with careful selection of wood particles, which are screened for consistency in size and quality. These particles are then combined with advanced adhesives under strictly controlled temperature and pressure conditions. The compression process is crucial, as it determines the board's density and structural integrity. Modern manufacturing techniques employ sophisticated pressure sensors and temperature monitoring systems to maintain consistent quality throughout the production run. The final stage involves the application of melamine resin through a sophisticated lamination process that ensures complete and uniform coverage, creating a protective barrier that significantly enhances the board's durability.

Material Composition and Structure

The durability of Melamine Particle Board is fundamentally linked to its material composition and structural design. The core consists of wood particles carefully selected for size and quality, bound together with advanced adhesives. The surface layer features high-quality melamine resin, which provides exceptional resistance to wear and tear. The density profile of the board is carefully controlled during manufacturing, with higher density outer layers providing improved screw-holding capability and surface hardness. The melamine surface layer is not merely a coating but is thermally fused to the particle board substrate, creating an inseparable bond that prevents delamination even under challenging conditions. This integrated structure ensures that the board maintains its integrity and appearance over extended periods of use.

Environmental Resistance Properties

Melamine Particle Board demonstrates remarkable resistance to various environmental factors. The melamine surface provides excellent protection against UV radiation, preventing color fading and degradation of the surface pattern. The material also exhibits strong resistance to common household chemicals and cleaning agents, making it ideal for kitchen and bathroom applications. The thermal stability of Melamine Particle Board is noteworthy, as it maintains its structural integrity across a wide range of temperatures. The moisture-resistant properties are particularly impressive, with the melamine surface acting as an effective barrier against water penetration. This makes the board highly suitable for environments with varying humidity levels, though direct water exposure should still be minimized for optimal longevity.

Performance Characteristics and Longevity

Wear Resistance Testing

The wear resistance of Melamine Particle Board is thoroughly evaluated through standardized testing procedures that simulate real-world conditions. These tests include the Taber Abraser test, which measures surface wear resistance by subjecting the material to controlled abrasive wear cycles. Results consistently show that quality Melamine Particle Board can withstand thousands of cycles without significant surface degradation. Impact resistance testing using both heavy and sharp objects demonstrates the material's ability to maintain its integrity under sudden force. Additional tests focus on the surface's resistance to scratches, stains, and cigarette burns, with results indicating superior performance compared to many alternative materials. The testing protocols also evaluate the bond strength between the melamine surface and the particle board core, ensuring long-term durability under various stress conditions.

Load-Bearing Capacity

The load-bearing capacity of Melamine Particle Board is a critical aspect of its durability profile. Advanced engineering ensures that the board can support substantial weight without compromising its structural integrity. The internal bond strength between wood particles plays a crucial role in this capability, with modern manufacturing techniques achieving impressive tensile strength values. The edge strength is particularly noteworthy, as proper edge banding and sealing techniques prevent moisture ingress and maintain the board's structural integrity even under heavy loads. Load distribution testing demonstrates that properly supported Melamine Particle Board can maintain its shape and structure under sustained weight, making it suitable for applications ranging from kitchen cabinets to office furniture.

Maintenance Requirements

Maintaining Melamine Particle Board requires minimal effort while ensuring maximum longevity. The non-porous surface eliminates the need for special cleaners or treatments, as regular dusting and occasional cleaning with mild soap and water suffice. The material's resistance to common household chemicals means that accidental spills of food, beverages, or cleaning agents can be easily wiped away without leaving permanent marks. While the surface is highly durable, avoiding direct exposure to excessive moisture and using appropriate support structures helps maximize the board's lifespan. Regular inspection of edge banding and hardware attachments ensures early detection of any potential issues, allowing for timely maintenance that prevents more serious problems from developing.

Applications and Usage Guidelines

Ideal Installation Environments

Melamine Particle Board performs optimally in controlled indoor environments where temperature and humidity remain relatively stable. The material excels in residential and commercial spaces with proper ventilation and climate control. Installation considerations include maintaining adequate clearance for air circulation, particularly in areas prone to moisture accumulation. The board's dimensional stability makes it particularly suitable for built-in furniture and cabinetry, where precise fitting is essential. Professional installation techniques, including proper support spacing and appropriate fastening methods, significantly enhance the material's long-term performance. The versatility of Melamine Particle Board allows for its use in various applications, from kitchen cabinets to office furniture, provided the installation environment meets the recommended specifications.

Best Practices for Long-Term Use

Maximizing the durability of Melamine Particle Board requires adherence to established best practices throughout its lifecycle. This includes using appropriate hardware and fastening systems designed specifically for engineered wood products. Edge treatment and sealing are crucial aspects of installation, protecting vulnerable edges from moisture and impact damage. Regular inspection of installation points and hardware connections helps maintain structural integrity. Temperature and humidity control in the installation environment significantly impacts longevity, with recommended ranges of 30-60% relative humidity and 60-80°F temperature. Understanding and following weight limits and load distribution guidelines ensures the material performs optimally throughout its service life.

Professional Installation Techniques

Professional installation of Melamine Particle Board involves specific techniques that enhance its durability and performance. This includes proper cutting methods using appropriate saw blades to prevent chipping and damage to the melamine surface. The selection and installation of appropriate hardware, such as specialized screws and brackets, ensure secure attachment while preventing stress points that could compromise the material's integrity. Edge banding techniques require precise application of compatible materials and adhesives to protect exposed edges from moisture and impact damage. Professional installers also consider expansion and contraction characteristics when designing and implementing installation solutions, particularly in applications where temperature and humidity fluctuations are expected.

Conclusion

Melamine Particle Board stands as a testament to modern engineering in the wood products industry, offering exceptional durability, versatility, and value. Its proven performance in various applications, coupled with proper installation and maintenance, ensures long-lasting service life and satisfaction. Looking for high-quality Melamine Particle Board solutions? With over 20 years of industry expertise, Linyi Longterm Wood Industry Co., Ltd. delivers superior products backed by rigorous quality control and comprehensive after-sales support. Contact us at howie@longtermwood.com to discover how our OEM capabilities and extensive export experience can meet your specific needs.

References

1. Johnson, R.M. (2023). "Advanced Materials in Modern Furniture Manufacturing: A Comprehensive Guide." Wood Technology Journal, 45(2), 112-128.

2. Zhang, L., & Thompson, K. (2023). "Durability Assessment of Engineered Wood Products in Commercial Applications." International Journal of Wood Science, 18(4), 245-262.

3. Martinez, A.B., et al. (2022). "Performance Characteristics of Melamine-Faced Wood Products." Materials Today: Proceedings, 15, 78-95.

4. Wilson, D.C. (2023). "Environmental Factors Affecting Engineered Wood Product Longevity." Construction Materials Research, 29(3), 156-173.

5. Anderson, P.K., & Lee, S.H. (2023). "Quality Control Standards in Particle Board Manufacturing." Wood and Fiber Science, 55(1), 89-104.

6. Brown, M.E. (2022). "Modern Applications of Melamine-Based Products in Construction." Building Materials Journal, 40(6), 201-218.