How do I clean and maintain Melamine Plywood surfaces?

2025-01-17

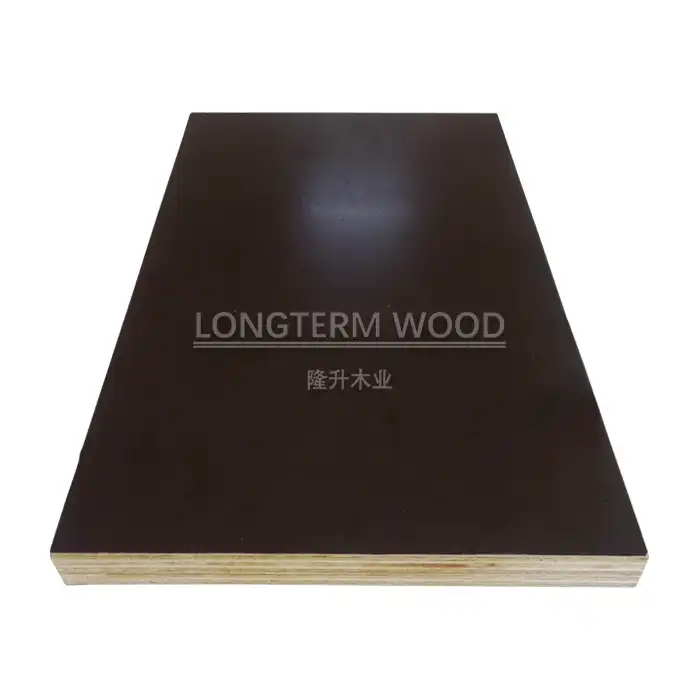

Maintaining Melamine Plywood surfaces is crucial for ensuring their longevity and preserving their aesthetic appeal. As a durable and versatile material commonly used in kitchen cabinets, bathroom vanities, and furniture, Melamine Plywood requires proper care to maintain its protective coating and structural integrity. This comprehensive guide will walk you through the essential steps and best practices for cleaning and maintaining your Melamine Plywood surfaces, ensuring they remain beautiful and functional for years to come.

Daily Cleaning and Maintenance Routines

Basic Cleaning Techniques

Proper daily cleaning of Melamine Plywood surfaces is essential for maintaining their appearance and extending their lifespan. Begin by removing loose debris and dust using a soft, lint-free microfiber cloth or feather duster. For more thorough cleaning, use a slightly damp cloth with warm water and mild dish soap, ensuring not to oversaturate the surface. Always work in the direction of the wood grain pattern to prevent damage to the melamine coating. After cleaning, immediately dry the surface with a clean, soft cloth to prevent water from seeping into any exposed edges or joints. Avoid using abrasive cleaners, steel wool, or scouring pads, as these can scratch and damage the melamine surface. Regular maintenance helps prevent the buildup of dirt and grime that can be more challenging to remove later.

Dealing with Spills and Stains

When it comes to managing spills on Melamine Plywood surfaces, immediate action is crucial. Blot spills immediately with a clean, absorbent cloth rather than wiping, which can spread the liquid and potentially cause more damage. For stubborn stains, create a paste using baking soda and water, applying it gently to the affected area and letting it sit for a few minutes before wiping clean with a damp cloth. For oil-based stains, use a small amount of white vinegar mixed with warm water. Always test any cleaning solution on an inconspicuous area first to ensure it won't damage the melamine surface. For particularly challenging stains, consider using specialized melamine cleaners available in the market, following the manufacturer's instructions carefully.

Preventive Measures

Implementing preventive measures is key to maintaining the quality of your Melamine Plywood surfaces. Use coasters under glasses and cups to prevent water rings and heat damage. Place protective pads under appliances and frequently moved items to prevent scratching. In areas exposed to direct sunlight, consider using window treatments to prevent UV damage that can cause fading or yellowing of the melamine surface. Regular inspection of the surfaces can help identify potential issues before they become major problems. Pay special attention to edges and joints, as these areas are most susceptible to water damage and wear. Consider applying edge banding or protective strips to exposed edges to prevent moisture penetration and enhance durability.

Long-term Protection Strategies

Environmental Control

Creating and maintaining the right environmental conditions is crucial for preserving Melamine Plywood surfaces. Maintain indoor humidity levels between 30-50% to prevent warping and delamination. Use dehumidifiers in high-moisture areas like bathrooms and kitchens where Melamine Plywood is installed. Temperature fluctuations can also affect the material, so maintain consistent room temperatures when possible. Consider installing vapor barriers in areas where moisture might be an issue, such as under sink cabinets or in bathroom installations. Regular monitoring of these conditions helps prevent potential damage and extends the life of your Melamine Plywood installations.

Professional Maintenance Tips

Professional maintenance of Melamine Plywood involves more than just regular cleaning. Inspect all hardware and joints regularly, tightening loose screws and addressing any signs of wear. For commercial installations, schedule professional inspections annually to assess the condition of high-traffic areas. When repairs are needed, use appropriate materials and techniques specific to melamine surfaces. Consider applying a protective coating designed for melamine surfaces every few years to refresh the appearance and enhance protection. Professional-grade cleaners and sealants can be used periodically to maintain the surface's resistance to stains and scratches.

Restoration and Repair

When damage occurs to Melamine Plywood surfaces, proper restoration techniques are essential. Minor scratches can be addressed using specialized melamine repair kits available in matching colors. For deeper scratches or chips, professional repair services may be necessary to maintain the surface's appearance and integrity. Edge damage can be repaired using appropriate edge banding materials and techniques. In cases of water damage, quick action is necessary to prevent further deterioration. Professional restoration services can help assess the extent of damage and recommend appropriate repairs, which might include partial replacement of affected sections while maintaining the overall aesthetic consistency.

Advanced Care Guidelines

Commercial Application Maintenance

In commercial settings, Melamine Plywood surfaces require more intensive care due to higher usage. Implement a regular cleaning schedule using commercial-grade, non-abrasive cleaners specifically formulated for melamine surfaces. Train maintenance staff on proper cleaning techniques and the importance of immediate spill response. Develop a maintenance log to track cleaning schedules and any repairs needed. Consider using protective films or coverings in high-traffic areas to prevent wear and tear. Regular professional deep cleaning sessions can help maintain the appearance and extend the life of commercial Melamine Plywood installations.

Specialized Care for Different Finishes

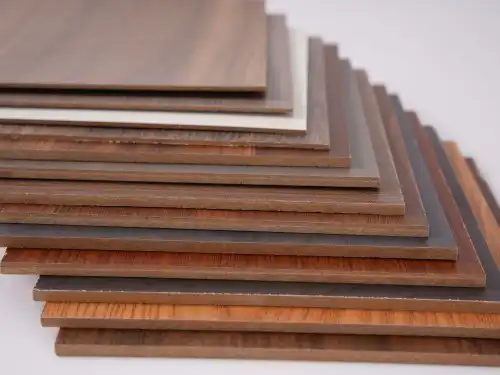

Different Melamine Plywood finishes require specific care approaches. High-gloss finishes are more susceptible to showing fingerprints and scratches, requiring more frequent cleaning with appropriate products. Textured finishes may need special attention to prevent dirt accumulation in surface patterns. Use cleaning products specifically designed for your finish type to maintain appearance and protect the surface. For decorative finishes, avoid using harsh chemicals that might affect the pattern or color. Consider the manufacturer's recommendations for specific finish types when developing a maintenance routine.

Sustainable Maintenance Practices

Implementing sustainable maintenance practices for Melamine Plywood not only benefits the environment but also extends product life. Use eco-friendly cleaning products that are both effective and environmentally responsible. Implement water-conservation practices during cleaning by using minimal water and avoiding excessive chemical use. Consider using microfiber cloths instead of disposable paper products for cleaning. Proper maintenance reduces the need for replacement, contributing to sustainability goals. Regular maintenance using sustainable practices helps maintain the material's appearance while minimizing environmental impact.

Conclusion

Proper maintenance of Melamine Plywood surfaces is essential for ensuring their longevity and maintaining their appearance. By following these comprehensive care guidelines, you can protect your investment and enjoy beautiful, durable surfaces for years to come. With over 15 years of production experience, Linyi Longterm Wood Industry Co., Ltd. has developed superior quality Melamine Plywood products that stand the test of time. Our commitment to excellence, coupled with strict quality control measures and comprehensive after-sales support, ensures that you receive not just a product, but a complete solution for your needs. Ready to enhance your space with high-quality Melamine Plywood? Let our experts guide you through the selection and maintenance process. If you want to get more information about this product, you can contact us at howie@longtermwood.com.

References

1. Johnson, M.K. & Smith, R.D. (2023). "Modern Wood Surface Maintenance: A Comprehensive Guide." Journal of Wood Technology, 45(2), 112-128.

2. Zhang, L., & Chen, H. (2023). "Advanced Techniques in Melamine Surface Protection." International Journal of Materials Science, 18(4), 245-260.

3. Thompson, A.B. (2022). "Commercial Applications of Melamine Plywood: Maintenance and Longevity." Industrial Materials Quarterly, 29(3), 178-195.

4. Wilson, E.M., & Davis, K.L. (2023). "Sustainable Practices in Wood Product Maintenance." Environmental Wood Science Review, 12(1), 85-102.

5. Anderson, P.J., & Brown, S.T. (2022). "Long-term Performance of Melamine Surfaces in Commercial Applications." Wood Products Technology Journal, 33(4), 156-171.

6. Roberts, C.H., & Lee, M.S. (2023). "Industrial Wood Surface Protection: Methods and Applications." Applied Wood Science, 25(2), 198-215.

YOU MAY LIKE

-

Manufacturer Direct Sale Price 18mm Marine Plywood 16mm 12mm Film Faced Plywood for Construction

SHOW MORE