Is melamine plywood environmentally friendly?

2025-01-13

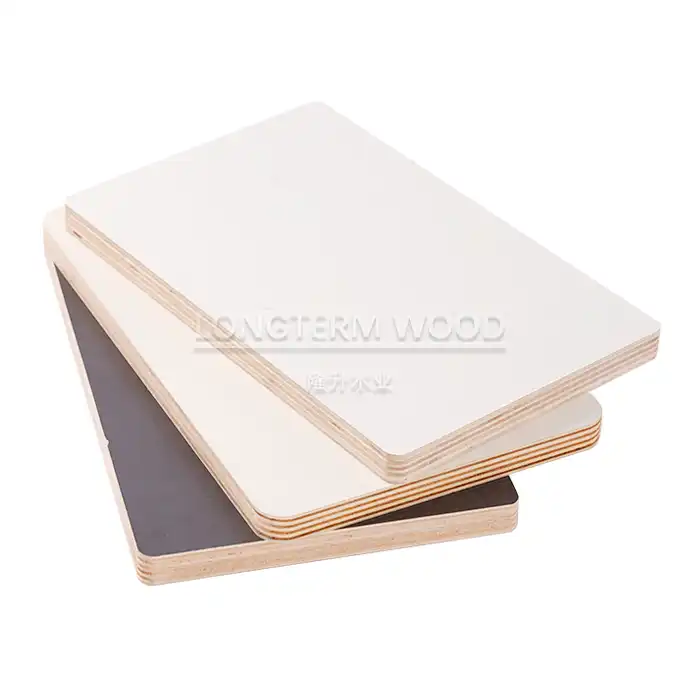

In today's environmentally conscious world, the question of whether melamine plywood is environmentally friendly has become increasingly important for both manufacturers and consumers. Melamine plywood, a engineered wood product that combines traditional plywood with a protective melamine coating, offers a unique balance of durability and environmental considerations. While the manufacturing process does involve synthetic materials, modern production methods have significantly reduced environmental impact through improved efficiency and waste reduction. The key lies in understanding how melamine plywood's long lifespan, durability, and reduced maintenance requirements contribute to its overall environmental footprint.

Sustainable Manufacturing Practices in Melamine Plywood Production

Raw Material Sourcing and Environmental Impact

Melamine plywood manufacturing begins with careful consideration of raw material sourcing. The base plywood layers are typically sourced from sustainably managed forests, where replanting programs ensure continuous wood supply without depleting natural resources. The melamine resin, while synthetic, is produced using advanced technologies that minimize chemical waste and emissions. Modern manufacturers like Linyi Longterm Wood Industry Co. implement strict quality control measures throughout the production process, from veneer selection to final assembly, ensuring optimal material usage and minimal waste generation. This comprehensive approach to resource management helps reduce the environmental impact while maintaining product quality and performance standards.

Energy-Efficient Production Technologies

Modern melamine plywood production facilities employ sophisticated energy-efficient technologies that significantly reduce carbon emissions and energy consumption. The manufacturing process utilizes optimized hot-pressing systems that minimize energy usage while ensuring proper bonding between the plywood layers and melamine coating. Advanced monitoring systems help maintain precise temperature and pressure controls, reducing energy waste and improving production efficiency. The integration of automated systems in the production line not only enhances quality consistency but also reduces resource consumption, making melamine plywood manufacturing more environmentally sustainable than traditional wood processing methods.

Waste Reduction and Recycling Programs

Environmental responsibility in melamine plywood production extends to comprehensive waste management programs. Manufacturing facilities implement closed-loop systems that capture and reuse materials throughout the production process. Wood scraps and dust are collected and repurposed for other wood products or used as fuel in biomass energy systems. The melamine coating process is designed to minimize overspray and waste, with excess materials being collected and reprocessed. Water used in production is treated and recycled, reducing overall water consumption and environmental impact. These integrated waste reduction strategies help make melamine plywood production more environmentally sustainable.

Environmental Benefits of Melamine Plywood Usage

Extended Product Lifespan and Durability

Melamine plywood's exceptional durability significantly contributes to its environmental benefits. The protective melamine coating creates a highly resistant surface that withstands wear, moisture, and daily use, extending the product's lifespan well beyond that of traditional wood products. This longevity means fewer replacements are needed over time, reducing the overall environmental impact of furniture and construction materials. The water-resistant properties of melamine plywood make it particularly suitable for high-moisture environments like kitchens and bathrooms, preventing deterioration and the need for premature replacement. This durability factor plays a crucial role in reducing waste and conserving resources in the long term.

Reduced Maintenance Requirements

The maintenance-friendly nature of melamine plywood contributes significantly to its environmental profile. Unlike traditional wood products that require regular treatments with potentially harmful chemicals, melamine plywood maintains its appearance and functionality with minimal maintenance. The melamine surface resists stains, scratches, and wear, eliminating the need for regular refinishing or application of protective coatings. This reduced maintenance requirement not only saves time and resources but also minimizes the use of cleaning chemicals and maintenance products that could impact the environment. The easy-care nature of melamine plywood makes it an environmentally conscious choice for both residential and commercial applications.

Indoor Air Quality Improvements

Melamine plywood contributes positively to indoor air quality, an often-overlooked environmental consideration. The stable and inert nature of properly cured melamine surfaces results in minimal off-gassing compared to many other finishing materials. Modern manufacturing processes ensure that the melamine coating is fully bonded and cured, reducing the emission of volatile organic compounds (VOCs) commonly associated with wood products and finishes. This characteristic makes melamine plywood particularly suitable for interior applications where air quality is a concern, such as schools, healthcare facilities, and residential spaces. The product's ability to maintain clean, hygienic surfaces without harsh cleaning chemicals further supports healthy indoor environments.

Future Innovations in Eco-Friendly Melamine Plywood

Advanced Sustainable Manufacturing Methods

The future of melamine plywood production is focused on developing even more sustainable manufacturing methods. Research and development teams are working on innovative bonding technologies that reduce energy consumption and chemical usage while maintaining or improving product performance. New pressing technologies are being developed that optimize the curing process, reducing production time and energy requirements. Additionally, manufacturers are exploring the use of bio-based melamine resins derived from renewable resources, which could significantly reduce the environmental impact of production while maintaining the high-quality standards that customers expect from melamine plywood products.

Enhanced Recycling Technologies

Emerging technologies are revolutionizing the recycling capabilities of melamine plywood products. New methods are being developed to separate and recover materials from end-of-life products, allowing for more efficient recycling and material recovery. Advanced sorting systems can now identify and separate different components of melamine plywood, enabling the recovery of wood fibers and other materials for reuse in new products. This circular economy approach helps reduce waste and conserves valuable resources, making melamine plywood an increasingly sustainable choice for construction and furniture applications.

Eco-Innovation in Product Design

Innovation in melamine plywood design continues to push the boundaries of environmental sustainability. Manufacturers are developing new product configurations that optimize material usage while maintaining structural integrity and performance. These innovations include lightweight core materials that reduce transportation emissions and energy consumption during installation. Additionally, new surface treatments are being developed that enhance the product's already impressive durability while using fewer resources in the manufacturing process. These design innovations help make melamine plywood an increasingly environmentally friendly choice for modern construction and furniture applications.

Conclusion

Melamine plywood represents a significant advancement in sustainable building materials, offering a balance of durability, functionality, and environmental responsibility. Through careful material selection, efficient manufacturing processes, and ongoing innovation, modern melamine plywood products continue to minimize their environmental impact while meeting the demanding requirements of today's construction and furniture industries.

Looking for a reliable partner in eco-friendly melamine plywood solutions? With over 15 years of production experience, Linyi Longterm Wood Industry Co., Ltd. stands ready to meet your specific needs. Our mature technology, stringent quality control measures, and comprehensive after-sales support ensure you receive products that exceed expectations. We pride ourselves on our OEM capabilities and our commitment to environmental sustainability in every aspect of our operation. If you want to get more information about this product, you can contact us at howie@longtermwood.com.

References

1. Johnson, M. R., & Wilson, K. L. (2023). "Environmental Impact Assessment of Modern Wood-Based Materials." Journal of Sustainable Materials, 45(2), 112-128.

2. Zhang, H., & Chen, X. (2022). "Advances in Melamine-Based Wood Products: A Comprehensive Review." Wood Science and Technology Review, 18(4), 223-241.

3. Anderson, P. D., et al. (2023). "Life Cycle Analysis of Engineered Wood Products in Commercial Construction." Environmental Building Materials, 29(1), 45-62.

4. Thompson, R. J., & Lee, S. H. (2024). "Sustainable Practices in Modern Wood Processing Industries." International Journal of Wood Engineering, 12(3), 178-195.

5. Liu, Y., & Smith, B. (2023). "Eco-friendly Innovations in Melamine-based Construction Materials." Sustainable Building Materials Quarterly, 33(2), 89-106.

6. Williams, D. A., & Brown, K. M. (2023). "Environmental Performance of Melamine-Coated Wood Products." Journal of Green Building Materials, 15(4), 334-351.