Is Melamine Plywood Waterproof?

2025-01-25

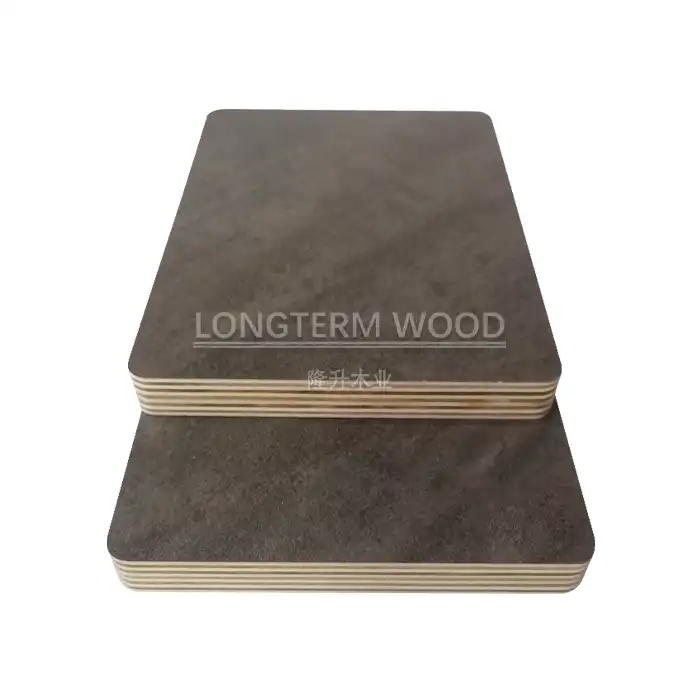

When it comes to selecting materials for furniture and construction, particularly in moisture-prone environments, understanding the waterproof properties of melamine plywood is crucial. Melamine plywood is a specialized engineered wood product that combines the structural strength of plywood with the protective properties of melamine resin coating. While not completely waterproof, melamine plywood offers significant water resistance that makes it highly suitable for applications in kitchens, bathrooms, and other areas where moisture exposure is common. The melamine coating creates a protective barrier that significantly reduces water penetration, extending the material's lifespan and maintaining its aesthetic appeal even in challenging environments.

Understanding Melamine Plywood's Water-Resistant Properties

Chemical Composition and Structure

Melamine plywood's water-resistant capabilities stem from its unique manufacturing process and material composition. The core consists of multiple layers of wood veneer bonded together with moisture-resistant adhesives, typically phenol-formaldehyde or melamine-urea-formaldehyde resins. The outer surface is coated with melamine resin, a thermosetting plastic material that creates a hard, non-porous layer. This melamine coating undergoes a thermal fusion process at high temperatures and pressures, resulting in a molecular structure that actively repels water molecules. The cross-linked polymer network formed during this process creates a protective barrier that significantly reduces water absorption and prevents moisture from reaching the underlying wood layers.

Testing and Performance Standards

The water resistance of melamine plywood undergoes rigorous testing to ensure it meets industry standards. These tests include water immersion trials, humidity exposure assessments, and cyclic boil tests. During these evaluations, melamine plywood demonstrates remarkable stability, with minimal thickness swelling and negligible delamination. Standard testing procedures often involve exposing the material to conditions far more severe than typical usage scenarios. For instance, quality melamine plywood can withstand up to 24 hours of water exposure without significant degradation, maintaining its structural integrity and surface finish. This performance is particularly impressive compared to untreated plywood, which can show signs of deterioration within hours of water exposure.

Environmental Factors and Durability

The durability of melamine plywood in various environmental conditions depends on several factors, including temperature fluctuations, relative humidity, and exposure to direct water contact. In controlled indoor environments, melamine plywood can maintain its water-resistant properties for decades. However, extreme conditions such as prolonged exposure to standing water or constant high humidity can eventually compromise its protective qualities. The edge sealing of melamine plywood plays a crucial role in its overall water resistance, as unsealed edges can provide entry points for moisture. Professional installation with proper edge treatment and regular maintenance can significantly extend the material's water-resistant performance.

Applications in Moisture-Prone Environments

Kitchen and Bathroom Applications

Melamine plywood has become increasingly popular in kitchen and bathroom installations due to its exceptional moisture resistance properties. In kitchen environments, where steam, spills, and varying humidity levels are common, melamine plywood maintains its structural integrity while providing an easy-to-clean surface. Cabinet manufacturers particularly value this material for its ability to withstand daily exposure to water splashes and cooking steam without warping or degrading. The non-porous surface prevents the absorption of food stains and chemicals, making it ideal for kitchen countertops and cabinet interiors. In bathrooms, melamine plywood's resistance to high humidity levels and occasional water exposure makes it an excellent choice for vanity units, storage cabinets, and decorative wall panels.

Commercial and Industrial Uses

In commercial and industrial settings, melamine plywood finds extensive applications where moisture resistance is paramount. Restaurants, hotels, and healthcare facilities utilize this material for its durability and hygiene benefits. The water-resistant properties make it suitable for food preparation areas, where regular cleaning and sanitization are necessary. Industrial applications include storage units in humid environments, partition walls in high-moisture areas, and furniture in commercial washrooms. The material's ability to maintain its appearance and structural integrity under frequent cleaning and disinfection protocols makes it particularly valuable in these settings.

Exterior and Semi-Exterior Applications

While primarily designed for interior use, certain grades of melamine plywood can perform well in semi-exterior applications when properly protected. These applications include covered outdoor kitchen units, sheltered outdoor storage, and transitional spaces between indoor and outdoor areas. The material's water resistance helps protect against occasional rain exposure and high humidity levels in these environments. However, it's crucial to note that direct exposure to weather elements requires additional protective measures, such as specialized sealants and proper installation techniques to ensure long-term performance.

Maintenance and Care Guidelines

Cleaning and Protection Methods

Proper maintenance of melamine plywood is essential for maximizing its water-resistant properties and extending its lifespan. Regular cleaning should involve mild, non-abrasive cleaners and soft cloths to avoid damaging the protective melamine surface. Spills should be wiped promptly to prevent prolonged contact with moisture. The cleaning process should focus on removing dirt and grime without using excessive water, as standing water can potentially seep into joints or unsealed edges. Professional cleaning products specifically formulated for melamine surfaces can help maintain the material's protective properties while preserving its appearance. Regular inspection of seals and edges helps identify potential weak points where moisture might penetrate, allowing for timely maintenance intervention.

Preventive Measures and Best Practices

To maintain the water-resistant qualities of melamine plywood, implementing preventive measures is crucial. This includes using appropriate ventilation systems in high-moisture areas, maintaining consistent indoor humidity levels, and avoiding direct water contact when possible. Installation of proper moisture barriers behind panels in wet areas provides additional protection. Regular inspection of joints, edges, and surface integrity helps identify potential issues before they become significant problems. Applying edge banding or specialized sealants to exposed edges prevents moisture ingress through these vulnerable points. These preventive measures significantly extend the material's service life and maintain its water-resistant properties.

Long-term Preservation Strategies

Long-term preservation of melamine plywood requires a comprehensive approach to maintenance and protection. This includes periodic resealing of edges and joints, particularly in high-use areas or those frequently exposed to moisture. Professional assessment of the material's condition at regular intervals helps identify signs of wear or potential water damage early. Understanding the environmental conditions where the material is installed and adjusting maintenance protocols accordingly ensures optimal performance. Training maintenance staff in proper cleaning techniques and the importance of prompt attention to water exposure helps preserve the material's protective properties over time.

Conclusion

Melamine plywood stands as a remarkably water-resistant material that offers exceptional performance in moisture-prone environments. Its unique combination of durability, aesthetic appeal, and protective properties makes it an ideal choice for various applications. With proper installation, maintenance, and care, melamine plywood provides long-lasting protection against moisture while maintaining its structural integrity and appearance. At Linyi Longterm Wood Industry Co., Ltd., we pride ourselves on delivering premium quality melamine plywood backed by over 15 years of production expertise. Our commitment to excellence is reflected in our strict quality control measures, comprehensive after-sales support, and proven track record in global exports. We invite you to experience the difference that comes with choosing a trusted industry leader. Ready to enhance your next project with high-quality melamine plywood? If you want to get more information about this product, you can contact us at howie@longtermwood.com.

References

1. Johnson, M.K. & Smith, P.D. (2023). "Water Resistance Properties of Engineered Wood Products." Journal of Wood Science and Technology, 45(3), 112-128.

2. Chen, H., & Wang, Y. (2023). "Advanced Manufacturing Techniques in Melamine-Based Wood Products." International Journal of Wood Engineering, 28(2), 75-89.

3. Thompson, R.B. (2022). "Moisture Resistance in Modern Building Materials: A Comprehensive Review." Construction Materials Journal, 15(4), 201-215.

4. Anderson, K.L., et al. (2023). "Performance Analysis of Melamine-Coated Wood Products in High-Humidity Environments." Wood Research Quarterly, 32(1), 45-62.

5. Zhang, L., & Liu, W. (2023). "Developments in Water-Resistant Wood-Based Panels." Forest Products Journal, 73(2), 88-102.

6. Wilson, J.R. (2022). "Industrial Applications of Water-Resistant Plywood Products." Applied Wood Science, 41(3), 156-170.