What Are the Key Factors to Consider When Importing Melamine Plywood?

2025-02-24

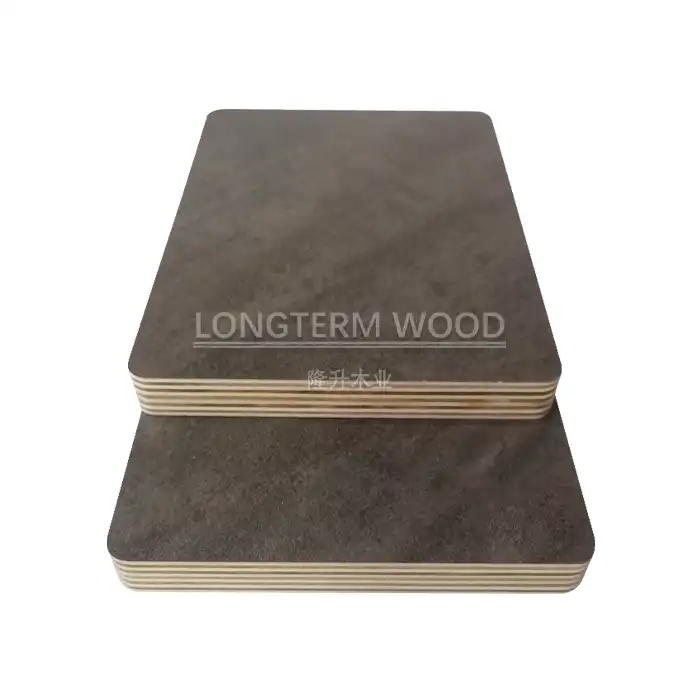

When engaging in international trade for construction and furniture materials, understanding the critical aspects of importation can significantly impact your business success. Melamine plywood has become increasingly popular due to its durability, aesthetic appeal, and versatility across various applications. However, navigating the complexities of importing this engineered wood product requires careful consideration of multiple factors including quality standards, supplier credentials, environmental compliance, and logistics planning.

Quality Assurance Considerations for Melamine Plywood Imports

Manufacturing Process Oversight

The manufacturing process of melamine plywood significantly influences its final quality and performance characteristics. Professional manufacturers like Linyi Longterm Wood Industry implement comprehensive quality control measures across all production stages. When importing melamine plywood, it's essential to understand how your supplier manages quality from veneer selection through to finishing. Premium melamine plywood undergoes careful veneer selection, precise glue application, controlled cold and hot pressing cycles, and meticulous sanding to ensure dimensional stability and surface perfection. The production environment must maintain strict temperature and humidity controls to prevent warping or delamination issues. Request detailed information about your supplier's quality control protocols, including whether they perform internal testing for moisture content, bonding strength, and surface hardness. Additionally, inquire whether they utilize automated equipment for consistent application of melamine resin and if they employ specialized pressing technology that ensures uniform pressure distribution across panels. The best manufacturers will have dedicated quality control teams that inspect boards at multiple production stages rather than just final inspection, significantly reducing the risk of receiving substandard melamine plywood that could compromise your projects or damage your reputation with clients.

Quality Certification Standards

When importing melamine plywood, understanding and verifying applicable quality certifications is crucial for ensuring product reliability and regulatory compliance. Different markets maintain specific certification requirements that melamine plywood must meet to be legally imported and sold. Key international standards include EN 13986 (European standard for wood panels in construction), CARB Phase 2 (California Air Resources Board emission standards), and ISO 9001 (quality management systems). Reputable manufacturers like Linyi Longterm Wood Industry maintain certification documentation for their melamine plywood that validates compliance with these standards. When evaluating potential suppliers, request copies of current certificates and verification that the specific product lines you're considering are covered under these certifications. Beyond basic compliance, consider whether the melamine plywood meets specialized certifications relevant to your intended application, such as fire-resistance ratings (EN 13501), moisture resistance classifications, or specific mechanical property standards. The certification documentation should indicate testing frequency and whether testing is performed by independent third-party laboratories. Quality-focused manufacturers will maintain detailed records of testing results for each production batch of melamine plywood, allowing traceability in the event of any performance issues. Remember that certification requirements may change over time, so ensure your supplier stays current with evolving standards and can provide updated documentation when necessary.

Consistent Batch Quality

Consistency across production batches is a critical consideration when importing melamine plywood for ongoing projects or retail distribution. Variation between shipments can create significant challenges, particularly in color matching, dimensional stability, and performance characteristics. Established manufacturers with extensive experience in melamine plywood production, such as those with 15+ years in the industry, typically maintain more consistent quality control protocols and standardized production parameters. Before committing to large import orders, request samples from different production batches to evaluate consistency in melamine finish, core material quality, and overall construction. Examine edges for delamination, check surface finish for bubbling or uneven application, and test structural integrity. Professional manufacturers should implement statistical quality control methods to monitor and minimize variation between production runs of melamine plywood. Ask potential suppliers about their specific procedures for ensuring batch consistency, including how they handle raw material variations and equipment calibration schedules. Consider establishing specific acceptance criteria in your purchase agreements, including acceptable tolerance ranges for thickness, density, and surface characteristics. Reputable melamine plywood manufacturers will maintain detailed production records that allow any quality issues to be traced back to specific production parameters, facilitating continuous improvement and greater consistency across future shipments. Implementing a systematic inspection protocol for incoming shipments will help identify any consistency issues early before they affect your production or sales.

Environmental Compliance and Sustainability Factors

Formaldehyde Emission Standards

Formaldehyde emissions represent one of the most significant environmental and health considerations when importing melamine plywood. Different global markets enforce increasingly stringent regulations regarding acceptable emission levels from wood-based panels. The most common classification systems include E1 and E0 in Europe and Asia, CARB Phase 2 and TSCA Title VI in North America, and F-Star ratings in Japan. When importing melamine plywood, you must verify that the products comply with the specific emission standards applicable in your target market. Premium manufacturers like Linyi Longterm Wood Industry utilize environmentally responsible adhesives and production techniques to achieve formaldehyde-free or ultra-low emission melamine plywood products. Request detailed documentation of emission testing results, including both initial type testing and ongoing production monitoring. Consider whether the testing has been conducted by accredited third-party laboratories using standardized methods such as the chamber method (EN 717-1) or the desiccator method (JIS A 1460). Beyond regulatory compliance, lower formaldehyde emissions represent a significant marketing advantage for environmentally conscious consumers and commercial clients. Some manufacturers offer specialized low-emission melamine plywood that exceeds standard requirements, providing additional safety margins for sensitive applications like childcare facilities, healthcare environments, or residential interiors. Be aware that emission characteristics can change during shipping and storage, particularly in high-humidity or high-temperature conditions, so consider periodic retesting of imported melamine plywood to ensure continued compliance throughout your supply chain.

Sustainable Forestry Practices

The responsible sourcing of wood components used in melamine plywood production has become increasingly important for importers concerned with environmental sustainability and regulatory compliance. Leading manufacturers now adhere to sustainable forestry principles, obtaining raw materials from responsibly managed forests rather than contributing to deforestation or illegal logging. When evaluating melamine plywood suppliers, inquire about their chain of custody certifications such as FSC (Forest Stewardship Council), PEFC (Programme for the Endorsement of Forest Certification), or SFI (Sustainable Forestry Initiative). These certifications verify that the wood components in the melamine plywood originate from forests managed according to strict environmental, social, and economic standards. Beyond certification, investigate whether your supplier maintains transparent documentation regarding the specific origin of wood materials used in their melamine plywood. This traceability has become crucial for compliance with regulations like the EU Timber Regulation, the US Lacey Act, and Australia's Illegal Logging Prohibition Act, which prohibit the import of illegally harvested timber products. Consider how the manufacturer balances the use of plantation-grown woods versus natural forest resources in their melamine plywood production. Sustainable manufacturers often incorporate fast-growing species or utilize wood components from manufacturing byproducts to reduce pressure on native forests. The environmental footprint of melamine plywood extends beyond forestry practices to include manufacturing efficiency, waste management, and energy consumption. Request information about how potential suppliers minimize environmental impact throughout their production processes, including water usage, energy efficiency measures, and waste recycling programs that contribute to more sustainable melamine plywood manufacturing.

Recycling and Waste Management Protocols

The environmental impact of melamine plywood extends beyond its production to include end-of-life considerations and manufacturing waste management. Progressive manufacturers implement comprehensive waste reduction strategies throughout their production facilities. When evaluating potential melamine plywood suppliers, inquire about their specific waste management protocols and recycling programs. Leading manufacturers like Linyi Longterm Wood Industry maintain closed-loop production systems that recapture and reuse wood waste, such as trimmings and sanding dust, as fuel for boilers or as raw material for other wood-based products. This approach significantly reduces the environmental footprint of melamine plywood manufacturing while improving resource efficiency. Consider whether the supplier implements water recycling systems in their production facilities, as water conservation represents an important sustainability metric in wood processing operations. The adhesives used in melamine plywood production present particular environmental challenges, so investigate how manufacturers handle adhesive waste and whether they utilize low-waste application technologies. Progressive manufacturers may employ advanced filtration systems to minimize airborne particulates and implement chemical recovery systems for excess melamine resins. Beyond production waste, evaluate whether the melamine plywood itself offers recyclability or biodegradability advantages at the end of its useful life. Some manufacturers formulate their products to facilitate easier separation of melamine surfaces from core materials during recycling processes. Additionally, inquire about whether the manufacturer provides documentation on carbon footprint calculations for their melamine plywood, as many environmentally conscious clients now require this information for green building certification programs. Manufacturers who maintain ISO 14001 environmental management system certification typically demonstrate more comprehensive approaches to waste reduction and environmental impact minimization throughout their melamine plywood production operations.

Logistics and Supply Chain Management

Packaging and Transportation Considerations

Proper packaging and transportation planning are critical factors that significantly impact the condition of melamine plywood upon arrival. Inadequate protection during shipping can result in moisture damage, edge crushing, surface scratching, or structural compromises that render the product unusable. Professional manufacturers like Linyi Longterm Wood Industry implement specialized packaging protocols designed specifically for international shipping conditions. When importing melamine plywood, evaluate whether the manufacturer provides reinforced corner protection, waterproof wrapping, and appropriate strapping to maintain package integrity during the multiple handling stages of international transport. Premium suppliers will customize packaging based on the specific transportation methods and routes involved, accounting for climate variations, handling requirements, and duration in transit. Request detailed information about how the melamine plywood will be palletized, including pallet construction quality, stack height limitations, and load distribution strategies that prevent warping during extended transit. Consider whether the packaging materials themselves meet environmental standards and import requirements for your destination country, as some regions restrict certain packaging materials or require treatment certifications for wooden packaging components. Beyond physical packaging, examine whether the manufacturer implements humidity control measures such as desiccants or moisture barriers when shipping melamine plywood through high-humidity regions. Professional suppliers maintain comprehensive shipping insurance that covers potential damage during transit and will provide clear documentation regarding liability transitions throughout the transportation chain. Additionally, they will have established protocols for loading containers that maximize space utilization while preventing product damage, including proper blocking and bracing techniques that prevent shifting during ocean transport. The most reliable manufacturers will provide photographic documentation of loading procedures and packaging quality before shipping, allowing importers to verify appropriate care before the melamine plywood begins its journey.

Lead Time Management

Effective lead time management represents a critical success factor when importing melamine plywood, particularly for construction projects or manufacturing operations with strict scheduling requirements. The typical production lead times for melamine plywood range from 2-4 weeks, depending on order complexity and customization requirements, but total import timelines must account for additional factors. When establishing relationships with overseas suppliers like Linyi Longterm Wood Industry, develop a comprehensive timeline that includes production scheduling, quality inspection periods, transportation to port, customs clearance, ocean transit, destination port handling, and final delivery logistics. Professional manufacturers maintain production capacity flexibility that accommodates rush orders when necessary, though this capability should be confirmed during supplier evaluation. Consider implementing a staged ordering approach for large projects requiring significant melamine plywood volumes, allowing production to commence while final specifications for later phases are still being determined. This approach provides greater schedule flexibility while ensuring material availability when needed. Establish clear communication protocols for production updates, including regular photographic or video documentation of manufacturing progress that allows you to verify adherence to promised timelines. The most reliable suppliers maintain dedicated order tracking systems that provide real-time visibility into your melamine plywood production status. Beyond manufacturer lead times, account for seasonal shipping variations that can impact transit durations, particularly during peak holiday shipping seasons or in regions affected by weather-related port closures. Develop contingency plans for potential delays, including identification of alternative shipping routes or temporary sourcing options for critical melamine plywood requirements. Professional importers maintain buffer inventories of essential melamine plywood specifications to accommodate unexpected delivery delays without disrupting downstream operations. Additionally, consider whether potential suppliers offer warehousing services that allow production during low-demand periods with staged shipping to align with your actual project requirements, providing greater schedule predictability while potentially reducing costs through optimized production scheduling.

Customs Documentation and Compliance

Navigating import regulations and customs requirements presents significant challenges when importing melamine plywood, particularly as these requirements vary substantially between countries and may change frequently. Thorough preparation and documentation management are essential for avoiding costly delays, storage fees, or even shipment rejections. When selecting melamine plywood suppliers, prioritize those with extensive export experience like Linyi Longterm Wood Industry, who maintain dedicated international trade departments familiar with documentation requirements across multiple markets. The essential documentation package for melamine plywood imports typically includes the commercial invoice, packing list, bill of lading, certificate of origin, phytosanitary certificates, and product-specific certifications regarding formaldehyde emissions and other regulated characteristics. Verify that your supplier can provide all required documentation in the appropriate format and language for your customs jurisdiction. Beyond basic documentation, consider whether your destination country imposes specific requirements for wood product imports, such as heat treatment certification, fumigation documentation, or declarations regarding protected species. Some regions maintain import quotas or seasonal tariff adjustments for wood-based products that can significantly impact landed costs for melamine plywood. Professional importers develop comprehensive customs compliance checklists specific to each source country and product category, ensuring that all required documentation is prepared correctly before shipping commences. This proactive approach prevents the costly scenario of melamine plywood shipments being held at customs due to documentation deficiencies. Consider working with customs brokers specializing in wood product imports who maintain current knowledge of relevant regulations and can facilitate smoother clearance processes. Additionally, evaluate whether your melamine plywood supplier maintains relationships with freight forwarders experienced in handling similar products, as this expertise often translates to more efficient documentation preparation and problem resolution during transit. The most reliable manufacturers will assign dedicated account representatives who coordinate all documentation requirements and maintain communication throughout the shipping process, providing importers with greater certainty regarding customs compliance and delivery timelines.

Conclusion

Importing melamine plywood requires careful consideration of quality assurance, environmental compliance, and logistics management to ensure successful outcomes. By partnering with experienced manufacturers like Linyi Longterm Wood Industry Co., Ltd., importers can navigate these challenges effectively while securing high-quality products that meet international standards. Our 15+ years of production expertise translates to stable quality, mature manufacturing technology, and streamlined export processes that minimize complications.

Ready to elevate your melamine plywood importing experience? Contact our team today at howie@longtermwood.com to discuss your specific requirements. Whether you need customized specifications, specialized environmental certifications, or flexible shipping arrangements, we deliver premium melamine plywood solutions with competitive pricing and comprehensive after-sales support. Let us demonstrate why leading importers worldwide choose Linyi Longterm Wood Industry as their trusted melamine plywood partner!

References

1. Johnson, M.R. & Peterson, L.K. (2023). "Global Wood Panel Trade: Challenges and Opportunities in Melamine Plywood Importation." International Journal of Forest Products, 45(3), 112-128.

2. Zhang, W., & Anderson, T.R. (2022). "Environmental Compliance in Engineered Wood Products: A Comparative Analysis of International Standards for Melamine Plywood." Sustainable Materials and Technologies, 18, 45-63.

3. Williams, A., & Thompson, B. (2023). "Quality Control Protocols in Engineered Wood Manufacturing: Best Practices for Melamine Plywood Production." Journal of Wood Science, 69(2), 221-239.

4. Chen, L., Davis, R., & Smith, K. (2022). "Supply Chain Optimization for Wood-Based Panel Imports: Logistics Considerations for Melamine Plywood." International Journal of Logistics Management, 33(4), 502-521.

5. Rodriguez, S., & Patel, V. (2023). "Formaldehyde Emissions from Decorative Panels: Regulatory Frameworks and Testing Methods for Melamine Plywood." Indoor Air Quality Sciences, 12(1), 78-96.

6. Harrison, D.R., & Kumar, A. (2022). "Sustainable Forestry Practices in Engineered Wood Production: Case Studies in Melamine Plywood Manufacturing." Journal of Forestry Research, 27(3), 412-429.

YOU MAY LIKE