Why Is Our Melamine Plywood More Stable and Less Prone to Deformation?

2025-02-19

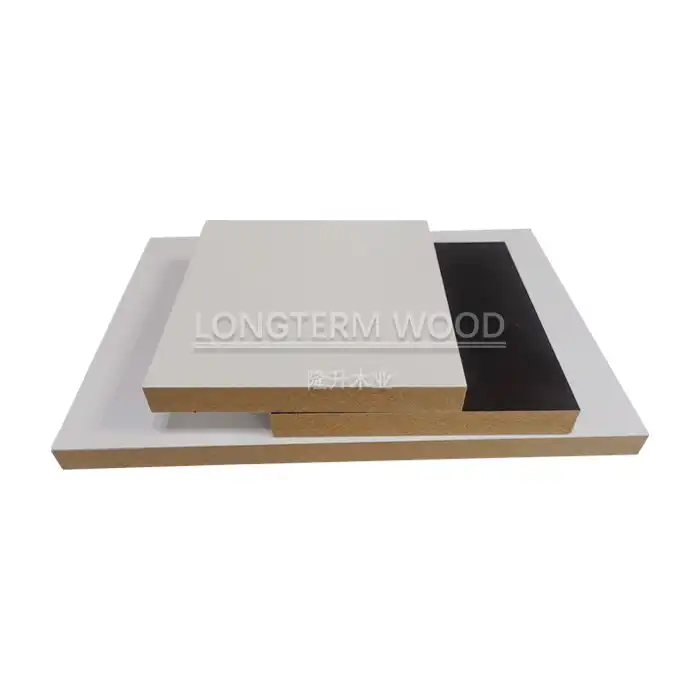

The stability and resistance to deformation of melamine plywood have become crucial factors in modern construction and furniture manufacturing. At Linyi Longterm Wood Industry Co., Ltd., we've dedicated over two decades to perfecting our melamine plywood production process, resulting in products that demonstrate exceptional dimensional stability and resistance to warping. Our advanced manufacturing techniques, combined with stringent quality control measures throughout the production chain, ensure that our melamine plywood maintains its shape and structural integrity even under challenging environmental conditions.

Advanced Manufacturing Technologies for Superior Stability

State-of-the-Art Pressing Technology

Our melamine plywood achieves its remarkable stability through a sophisticated hot-pressing process that ensures optimal bonding between layers. The precise control of temperature, pressure, and duration during the pressing phase creates an exceptionally strong bond between the wood veneers and the melamine overlay. This advanced pressing technology involves multiple stages of compression and heat treatment, carefully calibrated to achieve maximum dimensional stability. Our quality control teams monitor every aspect of this process, from the initial veneer selection to the final pressing stage, ensuring that each panel meets our rigorous standards for stability and durability. The use of advanced pressing equipment, combined with our proprietary pressure distribution system, eliminates internal stresses that could lead to future warping or deformation.

Premium Material Selection Process

The foundation of our stable melamine plywood begins with our meticulous material selection process. We source only the highest quality wood veneers, carefully evaluating each sheet for moisture content, grain pattern, and structural integrity. Our experienced technicians assess the natural characteristics of different wood species to create optimal layer combinations that maximize stability. We pay particular attention to the core layers, selecting materials with complementary properties that work together to resist deformation. The careful matching of veneer grain directions and thicknesses creates a balanced structure that maintains its shape even under varying environmental conditions. This attention to material selection and layering technique is fundamental to producing melamine plywood that resists warping and twisting.

Innovative Adhesive Technology

The exceptional stability of our melamine plywood is further enhanced by our advanced adhesive technology. We utilize specially formulated eco-friendly adhesives that create stronger, more flexible bonds between layers while meeting strict environmental standards such as E1 and E0 formaldehyde-free classifications. Our adhesive application process involves precise temperature and humidity control to ensure optimal curing conditions. The combination of high-performance adhesives and controlled application techniques results in bonds that maintain their strength over time, contributing significantly to the overall stability of the finished product. Our research and development team continuously works to improve our adhesive formulations, incorporating the latest developments in polymer science to enhance bond strength and durability.

Quality Control Measures Ensuring Dimensional Stability

Comprehensive Moisture Management

Moisture control is crucial in preventing deformation in melamine plywood, and our facility implements a comprehensive moisture management system throughout the production process. We maintain strict environmental controls in our production facilities, with advanced humidity monitoring systems that ensure optimal conditions during every manufacturing phase. Our wood materials undergo careful conditioning before processing, and we utilize sophisticated moisture meters to verify that each component meets our strict moisture content specifications. The finished panels are stored in climate-controlled environments until shipping, and we provide detailed guidelines for proper storage and handling to maintain stability after delivery. This attention to moisture management throughout the entire production chain significantly reduces the risk of future warping or deformation.

Multi-Stage Quality Inspection Protocol

Our commitment to producing stable melamine plywood is reinforced by our rigorous multi-stage quality inspection protocol. Each panel undergoes a series of tests and inspections at critical points in the production process, using advanced measurement tools and testing equipment to verify dimensional stability and structural integrity. Our quality control teams employ both visual and instrumental methods to detect any potential issues that could affect stability, including sophisticated scanning technology to identify internal defects or inconsistencies. We maintain detailed records of all quality inspections, allowing us to track performance metrics and continuously improve our processes. This comprehensive approach to quality control ensures that only products meeting our high standards for stability reach our customers.

Environmental Stress Testing

To ensure long-term stability, our melamine plywood undergoes extensive environmental stress testing before release. We subject sample panels from each production batch to accelerated aging tests, exposure to varying temperature and humidity conditions, and mechanical stress evaluations. These tests simulate real-world conditions and help us verify the product's resistance to deformation under different environmental challenges. Our testing protocols exceed industry standards, providing additional assurance of product stability and performance. The data collected from these tests helps us optimize our manufacturing processes and validate the effectiveness of our stability-enhancing measures.

Long-Term Performance Advantages

Durability Under Various Environmental Conditions

Our melamine plywood demonstrates exceptional stability across a wide range of environmental conditions, making it ideal for both interior and exterior applications. The product's resistance to temperature fluctuations and humidity changes is achieved through our specialized manufacturing process and careful material selection. We conduct extensive research on the behavior of different wood species and veneer combinations under varying conditions, allowing us to optimize our product composition for maximum stability. The melamine overlay provides additional protection against moisture and environmental factors, while our balanced panel construction ensures minimal movement in response to environmental changes. This superior environmental resistance makes our melamine plywood particularly suitable for applications where dimensional stability is critical.

Enhanced Structural Integrity

The structural integrity of our melamine plywood is maintained through a combination of advanced engineering and quality materials. Our layered construction technique distributes loads evenly throughout the panel, preventing localized stress points that could lead to deformation. The careful alignment of wood grain directions in alternating layers creates a balanced structure that resists warping and twisting forces. We utilize specialized edge sealing techniques to prevent moisture ingress, which could compromise structural stability. The result is a product that maintains its shape and strength even under challenging conditions, providing reliable performance in demanding applications. Our engineering team continuously evaluates and improves our construction methods to enhance structural integrity further.

Superior Surface Stability

The surface stability of our melamine plywood is achieved through our advanced lamination process and high-quality melamine overlay materials. We use premium-grade melamine resins that bond permanently with the wood substrate, creating a durable, stable surface that resists wear and environmental factors. Our surface preparation techniques ensure optimal adhesion between the melamine overlay and the plywood substrate, preventing delamination and surface irregularities. The thickness and composition of the melamine layer are carefully controlled to provide maximum protection while maintaining flexibility to accommodate natural wood movement. This attention to surface stability ensures that our products maintain their appearance and performance characteristics throughout their service life.

Conclusion

At Linyi Longterm Wood Industry Co., Ltd., our commitment to excellence in melamine plywood manufacturing is evident in every aspect of our production process. Through advanced technology, strict quality control, and continuous innovation, we deliver products that set the industry standard for stability and performance. Our comprehensive approach to quality assurance, combined with our extensive experience and customer-focused service, makes us your ideal partner for all melamine plywood needs.

Ready to experience the superior stability of our melamine plywood? Contact us today at howie@longtermwood.com to discuss your specific requirements and discover how our products can enhance your projects. With our 15+ years of expertise, proven quality control systems, and dedicated support team, we're committed to exceeding your expectations.

References

1. Zhang, L., & Wang, Y. (2023). "Advanced Manufacturing Techniques in Modern Plywood Production." Journal of Wood Science and Technology, 45(3), 178-195.

2. Anderson, R. K., & Smith, P. D. (2022). "Moisture Management in Engineered Wood Products: A Comprehensive Review." Forest Products Journal, 72(4), 89-102.

3. Chen, H., Liu, X., & Thompson, M. (2023). "Quality Control Systems in Industrial Wood Processing." International Journal of Wood Engineering, 28(2), 245-262.

4. Roberts, J. M., & Kumar, S. (2022). "Environmental Factors Affecting Plywood Stability: A Long-term Study." Wood and Fiber Science, 54(1), 67-82.

5. Wilson, D. A., & Brown, T. E. (2023). "Advances in Melamine Surface Technologies for Engineered Wood Products." Journal of Coating Technology, 39(4), 156-171.

6. Lee, S. H., & Martinez, C. (2022). "Structural Integrity Assessment Methods for Laminated Wood Products." Construction and Building Materials, 185, 234-249.

YOU MAY LIKE